Items filtered by date: Saturday, 13 December 2025

WearCheck Training. Africa & Beyond.

Ghana, Zimbabwe

WearCheck training manager Ashley Mayer conducts oil analysis courses for South African customers as well as those in exotic locations. Recently, he travelled to West Africa and Zimbabwe to offer training courses.

Ashley Mayer (front row under banner, blue shirt) is seen with African Mining Services delegates who attended an oil analysis course at a mine site in Zimbabwe recently.

Workers from AngloGold’s Ashanti site at Iduapriem in Ghana listen attentively to WearCheck training manager Ashley Mayer.

Abu Dhabi, Dubai

Steven Lumley, WearCheck technical manager, travelled to the Middle East to attend a conference and to run some training courses for customers in the region. She conducted a training course for employees of the NDC (National Drilling Corporation) of Abu Dhabi, and a course for Al Shirawi employees in Dubai.

Steven Lumley talks delegates through water contamination and oil analysis in Abu Dhabi recently.

Steven Lumley conducted oil analysis training for delegates of Al Shirawi in Dubai recently. She is pictured here (third from right) with some of her students.

Out and about

WearCheck staff members from various branches have clocked up some big air-miles lately, attending conferences, meetings and expos in several countries to stay abreast with the latest technology and to learn more about the evolving needs of industry.

WACA

The annual West and Central African Mining Summit & Expo (WACA) takes place in Accra, Ghana. This year, the WearCheck guys who were on-site to meet prospective customers and to talk condition monitoring, included Daniel Boakye, manager of WearCheck Ghana, and Pierre de Villiers, senior technician.

MINEX

Iran hosted the 5th annual Mines and Mining Industry Expo (MINEX), featuring the latest mining innovations for Iran and the Middle East. This year, WearCheck was present for the first time. Managing director Neil Robinson and Peter Safadi, manager of WearCheck PM Dubai were on hand to meet delegates. Neil was interviewed by an Iranian TV station, where he talked about condition monitoring.

WearCheck MD Neil Robinson is interviewed by Iranian TV at this year’s MINEX show in Tehran.

Seen at MINEX in Iran recently were Peter Safadi of WearCheck PM Dubai, Kevin Gerber of Set Point Laboratories and Neil Robinson, WearCheck MD.

MENA

The Middle East Mining Congress (MENA) once again took place in Dubai recently. This expo, which features “everything mining”, was attended by WearCheck for the first time.

On hand to meet and greet delegates at MENA in Dubai, were Peter Safadi (WearCheck PM Dubai manager), Steven Lumley (technical manager), Ingy Elazizi and MD Neil Robinson.

WINDABA

Wind energy is a burgeoning source of alternative power, and the focus of Windaba, as Africa’s premier Wind Energy Conference, dovetails well with WearCheck’s wind turbine condition monitoring programme. Attending Cape Town’s 2016 Windaba expo from WearCheck were Steven Lumley (technical manager), diagnostician Quintin Verster and reliability solutions manager Philip Schutte.

Loyalty Recognised

WearCheck is a family of very dedicated and loyal staff members, many of whom have clocked up several decades with the company. HR Manager Michelle Padayachee commended all long-serving staff, particularly those who reached important milestones recently.

‘Your loyalty and experience benefits both the company as well as our customers – helping us to continue to run the business efficiently and to offer excellent customer service. Thank you for your loyalty.’

Captions:

Image 1: Springs-based reliability solutions technician Frank Nkuna has worked at WearCheck for 10 years.

Image 2: Pinetown lab assistant Malcolm Govender has worked at WearCheck for 15 years.

Image 3: Isando-based reliability solutions technician Marcelle Symons has worked at WearCheck for 10 years.

Image 4: Ellisras-based reliability solutions technician Simon Mosima has worked at WearCheck for 10 years.

Image 5: Johannesburg-based driver Danny Nkomo has worked at WearCheck for 10 years.

Super Rugby Super Rugby Super Rugby

Rugby fan? Get your diary out!

The Super Rugby season kicks off on 23 February with the Rebels taking on the Bulls at AAMI stadium in Melbourne, Australia, culminating with a battle on 5th August between the finalist teams.

Recognised as the preeminent professional men's rugby union football competition, Super Rugby features playoffs between regional rugby teams based in the Southern Hemisphere and Japan.

To help you avoid the scrum for information, the WearCheck team has drop-kicked the Super Rugby viewing schedule directly to you – for match information, teams, venues and scores, please visit our facebook page or download from here

CLICK HERE to download the WearCheck Super Rugby Viewing Schedule

Let’s hear it for your favourite team…. (other than WearCheck, of course!). Happy viewing!

Train for Productivity

As oil analysis and reliability solutions are increasingly complex fields which are constantly evolving with new technology, WearCheck offers a variety of training courses for several levels of staff, targeted at workers in the maintenance and management arenas.

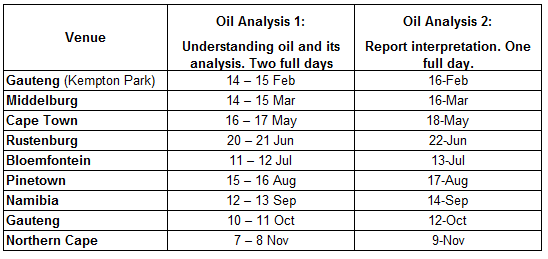

WEARCHECK 2017 OIL ANALYSIS TRAINING COURSES

Efficiency, speed and reducing the need to redo tasks – these are just some of excellent returns on investment for businesses that train their employees to do their jobs competently.

This is reinforced through the words of management guru Peter Drucker, ‘If you think training is expensive, try ignorance.’

Oil Analysis One covers two full days and costs R5 540. Oil Analysis Two and the NetCheck course cover one full day each and each costs R2 795.

Courses include course material, lunch, refreshments, giveaways and certificates. Prices exclude VAT and are subject to change. All courses can also be presented at the customer’s premises for a minimum of six delegates.

Other on-site courses: WearCheck Practical (in English or Zulu), a half day course costing R650 plus VAT per delegate, and WearCheck Customised – oil analysis for workshop technicians, a full day course costing R1 525 plus VAT per delegate.

For on-site training, there may be an additional charge for the lecturer’s travel and accommodation, if needed.

Training courses can be arranged anywhere.

For more details on course content, view Training at www.wearcheck.co.za. For bookings phone Kay Meyrick on (031) 700-5460 or email This email address is being protected from spambots. You need JavaScript enabled to view it..

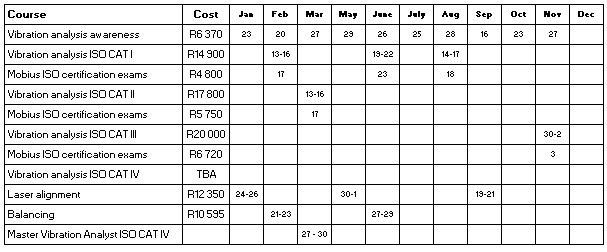

RELIABILITY SOLUTIONS TRAINING COURSES

Mobius training is offered in 153 countries, and is recognised the world over as the preferred standard for reliability solutions technicians. Mobius courses are run by WearCheck and presented either on-site or at the ABB School of Maintenance premises.

Courses include Alignment, Balancing, Awareness, and CAT I to III, and costs (excl VAT) are as follows, when presented at the ABB venue at 2 Lake Road, Longmeadow Business Park, Modderfontein, Johannesburg, South Africa.:

Courses can be presented on-site, and will be quoted accordingly

To book any of the above courses, or get course dates for the second half of 2017, please contact Dennis Swanepoel on 082 878-1578 or email This email address is being protected from spambots. You need JavaScript enabled to view it., or contact Christene Fourie on (011) 392-6322 or email This email address is being protected from spambots. You need JavaScript enabled to view it.

Mining Indaba 2017

The WearCheck team will once again be at Mining Indaba this year, showcasing our traditional condition monitoring options - Oil and Fuel analysis - as well as our extensive range of Reliability Solutions services.

Our technicians and diagnosticians will be at the stand daily to answer your questions about how investing in condition monitoring can SAVE YOU TIME AND MONEY!!

The mining industry in Africa is WearCheck’s largest customer base, and we pride ourselves on retaining our lead as one of the continent’s top condition monitoring companies through constant investment in the latest international technology, techniques and training.

Please come and visit us at Mining Indaba at the Cape Town ICC from 6 to 9 February, you will find us at Stand 804.

Prestigious peer review

WearCheck's diagnostic manager, John Evans, who - in his more than 25 years with the company - has had many of his articles published in many scientific journals in several countries, has diagnosed over a million samples, has conducted many training courses and is widely recognised as an inveterate expert in the oil analysis field.

WearCheck, and John, were recently honoured when John was invited to conduct a peer review on a manual chapter written by two American scientists, entitled "Particle Counting: Fuels and Lubricants" for the ASTM-Books.

Reviewing papers for publication is perhaps the highest mark of respect bestowed upon a researcher. To be asked to review a scientific paper is an acknowledgment of a researcher's superior knowledge and experience.

Well done, John, you have done WearCheck proud.

MINEX

Iran hosted the 5th annual Mines and Mining Industry Expo (MINEX), featuring the latest mining innovations for Iran and the Middle East. This year, WearCheck was present for the first time. Managing director Neil Robinson and Peter Safadi, manager of WearCheck PM Dubai were on hand to meet delegates. Neil was interviewed by an Iranian TV station, where he talked about condition monitoring.

WearCheck MD Neil Robinson is interviewed by Iranian TV at this year’s MINEX show in Tehran.

Monitor Issue 73

2016 was a busy year indeed for WearCheck...celebrating 40 years of condition monitoring excellence, reaching an important SABS milestone, attending many international and local conferences and expos and installing some high-tech new laboratory equipment.

Have a look at Monitor 73 to read more about these stories, as well as WearCheck’s popular new bypass filter, and find the answer to the question on everyone’s lips…WHO won the fabulous Samsung tablet? (The lucky draw prize for the customer services survey respondents)!

Under the Technical Tip section diagnostics manager John Evans explains in detail how to react to your sample report.

Click here to read about these and other stories.

Clean oil, clean fuel save money

Condition monitoring specialists, WearCheck, have now extended their fuels, lubricants, air and coolants (F.L.A.C) maintenance programme to include unique bypass filters, which minimise contaminants, thereby extending the life of the oil or fuel.

The filters were initially trialled at a chrome mine on three GHH machines running air-cooled motors. Once proven effective, the filters were then fitted to a further 27 machines in the same mine. The mine has already recorded savings of R1.7 million after paying for the implementation of the WearCheck programme.

Also known as depth filters, the bypass filters are bolted externally on each component, and the oil or fuel of that component passes through the filtration system, similar to how an individual dialysis machine would assist a patient to filter their own blood.

Oil or fuel typically passes through three filters – first the OEM water separator, next the OEM diesel filter, and finally WearCheck’s depth filter, which is last in line, and which provides extremely fine microfiltration, screening particles between 0.5 and 1 microns in diameter.

Chris Hattingh (operations/ technical support for WearCheck), outlines some of the advantages of the process, ‘By ensuring the fuel at the injector tip in a diesel engine is super-clean, it protects the moving parts and keeps these within spec for much longer, allowing for better atomisation.

‘Cleaner fuel burns with more power, therefore there are less by-products passing into the oil, such as soot. This means that lube oil can potentially last longer – and the additive packages don’t have to work as hard, so they last longer too.

‘By using scientific data on the oil’s condition, we can advise customers when it is feasible to extend the oil drain interval without risk, thereby saving them money. The filters function best as part of a comprehensive condition monitoring programme.’

Caption: Bolted externally onto the machine is one of WearCheck’s bypass filters for the transmission. The filters have already saved a mine over R1.5 million during an initial trial process.