Items filtered by date: Tuesday, 16 December 2025

Lube Tip 7: Hydraulic Fluids

Keep hydraulic fluids cool. (The bulk oil temperature at the exterior of the reservoir should never exceed 60°C).

Keep hydraulic fluids clean. (There is general agreement among hydraulic experts that 75 - 80 per cent of hydraulic failures are caused by fluid contaminated with dirt, wear particles and other foreign material. In today's high-pressure systems, clearances between wear surfaces are very small, making contamination control critical).

Immediately repair fluid leaks. If oil can escape, dirt and dust can re-enter the system. (A fluid leak of one drop per second is equal to 400 gallons in a 12-month period.)

(From "The Practical Handbook of Machinery Lubrication")

Mobius training for reliability solutions

As the certified Mobius training centre for the entire African continent, WearCheck runs Mobius courses on request from customers, on-site at the customer’s premises, anywhere in Africa (apart from SA, DRC and Kenya).

The full Mobius course includes compulsory six month practical training sessions. Participants are guided by WearCheck expertise that has been gained through the successful implementation of condition monitoring programmes tailored to meet the specific needs of operating, engineering and maintenance departments across a range of industries. Through these practical sessions, the skills of the technicians are developed in order to progress to the next level.

The Mobius Institute is a worldwide provider of education in reliability improvement, condition monitoring and precision maintenance, to industrial plant managers, reliability engineers and condition monitoring technicians.

The Mobius Institute Board of Certification (MIBoC) is ISO/IEC 17024 and ISO 18436 accredited, providing globally-recognised certification to category I-IV vibration analysts in accordance with ISO 18436-1 and 18436-2.

Mobius courses are run by WearCheck anywhere, any date, on demand.

- One day vibration analysis awareness: R 6 370 per delegate (group rates and on-site training days available on request)

- Two day laser alignment: R10 595

- Two day balancing: R10 595

- Three day CAT I: R15 000 (excl. exam)

- CAT I exam R4 134

- Four day CAT II: R18 000

- CAT II exam R4 941

- Four day Cat III: R22 000

- CAT III exam R5 751

- Five day CAT IV: TBA

*prices exclude VAT, and are valid until the end of 2018.

Note: a minimum of six candidates is required for all training courses. There may be an additional charge for the lecturer’s accommodation and travel.

To book a Mobius training course, please contact Christene on This email address is being protected from spambots. You need JavaScript enabled to view it. or Dennis Swanepoel on This email address is being protected from spambots. You need JavaScript enabled to view it. or call WearCheck Johannesburg on (011) 392-6322.

Click here to download our Mobius Training Schedules for 2018

Lube Tip 6: Different loads need lubricants with different properties

There are different degrees of severity under which boundary lubrication conditions prevail. Some are only moderate, while others are extreme. Boundary conditions are met by a variety of special lubricants with properties corresponding to the severity of the particular application.

These properties are derived from various additives contained in the oil — some singly and some in combination with other additives. Their effect is to increase the load-carrying ability of the oil.

Where loads are only mildly severe, an additive of the class known as oiliness agents or film-strength additives is applicable. Worm-gear and pneumatic-tool lubricants are often fortified with these types of agents.

Where loads are moderately severe, anti-wear agents or mild EP additives are used. These additives are particularly desirable in hydraulic oils and engine oils.

For more heavily loaded parts, a more potent class of additives is required. These are called extreme pressure (EP) agents.

-From the book "Practical Lubrication for Industrial Facilities":

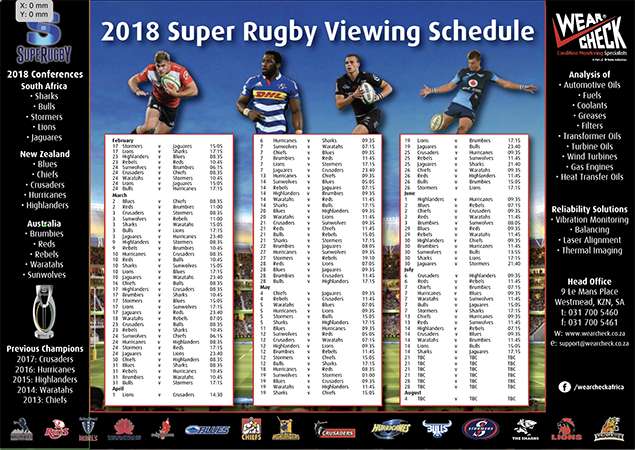

2018 Super Rugby – don’t miss a match!

If you’re a rugby fan, like we are, then take note – this year’s Super Rugby viewing schedule can be downloaded for free on our website.

15 teams from South Africa, New Zealand, Australia, Argentina and Japan will battle it out on the rugby field to see who will emerge as champions, kicking off on 17 February with a match between the Stormers and the Jaguares from Argentina.

The final conference match is on the 14 July, when the Sharks take on the Jaguares. Thereafter, the semi-finals take place in July, culminating in the final match to determine which team gets to take home the winner’s trophy on 4 August.

Click here to download our match schedule (Download Size: 6.5mb)

Lube Tip 5: Synthetic Oils vs. Mineral Oils

Query: “Relating to gearboxes on trucks, if the owner/ driver doesn’t know if the gear lubes are synthetic, is there a fool-proof way to determine this without having to send a sample to the lab? Some oil manufacturers colour their synthetic oils, while others don’t. What would happen if the oils were to be mixed or topped up with the wrong oil?”

WearCheck’s answer: The colour of the lube is simply a dye. There are no standards, and manufacturers can and do change colours whenever they please. Unfortunately, there is no reliable way of differentiating between mineral and synthetic in the field. However, because synthetic base oils are white (meaning transparent) as compared to mineral oils, which have a darker natural colour (due to aromatics, sulphur and other impurities), this may be a distinguishing factor. Note, however, that despite the fact that the base oil of a synthetic is white, the additives can add considerable colour (darkening) to the finished oil.

In the laboratory, you could distinguish synthetics from mineral oil by looking at a combination of physical properties including VI, flash point, pour point and aniline point. There may also be different elemental additive chemistry.

Generally, in the type of application you are talking about, the synthetic gear oil will likely be polyalphaolefin (PAO) based. PAOs are very similar chemically to mineral oils, so mixing the two should not cause a compatibility problem, especially if both oils are the same API classification.

However, if a synthetic is required, such as for cold-temperature operation, using a mineral by mistake may cause other problems.

Also, be aware that in industrial applications, some synthetic gear oils are polyglycol (PAG) base stocks, which are chemically incompatible with both PAO synthetics and mineral oils. In this case, mixing will result in serious incompatibility issues.

We're Hiring

WearCheck Reliability Solutions Division Vacancies

Senior Technician (Vibration)

Lethabo Power Station

Main Job Functions

- Responsible to plan, supervise and undertake work related to the providing of a professional CBM service to Eskom Power Station

- To undertake and ensure that all CBM services and work are carried out according to company policies and procedures

- Ensuring that Failure Analyses are carried out on equipment tested and providing the customer action and Recommendation Report

Minimum Requirements

- National Electrical/Mechanical Certificate N6

- Mechanical Fitter with 4 years Trade Test

- ISO 18436 Level 3 Vibration

- More than 8 years experience

- Intermediate Computer Skills

Desirable Qualities

Methodical, accurate, technically minded, good organisational skills, exhibit high level innovation and motivation, high attention to detail, team player, conscientious, energetic, good time management and ability to work under pressure.

Responsibilities and Duties

- Machine configuration as per SOP

- Compiling of routine reports in RBMView

- Compiling bi-annual Management report

- Collection of data for Analysis

- Alignment, Balancing, Thermography, Motor Current Analysis and Oil Sampling

Availability: The successful candidate must be able to start in their position as soon as possible.

Only CV’s sent to This email address is being protected from spambots. You need JavaScript enabled to view it. will be considered.

Applications close on 26th January 2018. If you have not received a response by 7th February 2018, please consider your application as being unsuccessful.

__________________________________________________________________________________

Technician (Vibration/Oil)

Matimba Power Station

Main Job Functions

- Responsible to plan, supervise and undertake work related to the providing of a professional CBM service to RS Division customers

- To undertake and ensure that all CBM services and work are carried out according to Company policies and procedures

- Ensuring that Failure Analyses are carried out on equipment tested and providing the Customer Action and Recommendation Report

Minimum Requirements

- National Electrical/Mechanical Certificate N3

- Mechanical Fitter with 2 years Trade Test

- ISO 18436 Level 2 Vibration

- Oil Level 2, with 3 years experience

- More than 4 years experience

- Intermediate Computer Skills

Desirable Qualities

Methodical, accurate, technically minded, good organisational skills, exhibit high level innovation and motivation, high attention to detail, team player, conscientious, energetic, good time management and ability to work under pressure.

Responsibilities and Duties

- Machine configuration as per SOP

- Compiling of routine reports in RBMView

- Compiling bi-annual Management report

- Collection of data for Analysis

- Vibration Analysis, Alignment, Balancing, Thermography, Motor Current Analysis and Oil Sampling

Availability: The successful candidate must be able to start in their position as soon as possible.

Only CV’s sent to This email address is being protected from spambots. You need JavaScript enabled to view it. will be considered.

Applications close on 26th January 2018. If you have not received a response by 7th February 2018, please consider your application as being unsuccessful.

__________________________________________________________________________________

Vibration Technician

Camden Power Station

Main Job Functions

- Responsible to plan, supervise and undertake work related to the providing of a professional CBM service to RS Division customers

- To undertake and ensure that all CBM services and work are carried out according to Company policies and procedures

- Ensuring that Failure Analyses are carried out on equipment tested and providing the Customer Action and Recommendation Report

Minimum Requirements

- National Electrical/Mechanical Certificate N3

- Mechanical Fitter with 2 years Trade Test

- ISO 18436 Level 2 Vibration

- Oil Level 2, with 3 years experience

- More than 4 years experience

- Intermediate Computer Skills

Desirable Qualities

Methodical, accurate, technically minded, good organisational skills, exhibit high level innovation and motivation, high attention to detail, team player, conscientious, energetic, good time management and ability to work under pressure.

Responsibilities and Duties

- Machine configuration as per SOP

- Compiling of routine reports in RBMView

- Compiling bi-annual Management report

- Collection of data for Analysis

- Vibration Analysis, Alignment, Balancing, Thermography, Motor Current Analysis and Oil Sampling

Availability: The successful candidate must be able to start in their position as soon as possible.

Only CV’s sent to This email address is being protected from spambots. You need JavaScript enabled to view it. will be considered.

Applications close on 26th January 2018. If you have not received a response by 7th February 2018, please consider your application as being unsuccessful.

__________________________________________________________________________________

Vibration Technician

Hillside Richards Bay

Main Job Functions

- Responsible to plan, supervise and undertake work related to the providing of a professional CBM service to RS Division customers

- To undertake and ensure that all CBM services and work are carried out according to Company policies and procedures

- Ensuring that Failure Analyses are carried out on equipment tested and providing the Customer Action and Recommendation Report

Minimum Requirements

- National Electrical/Mechanical Certificate N3

- Mechanical Fitter with 2 years Trade Test

- ISO 18436 Level 2 Vibration

- More than 4 years experience

- Intermediate Computer Skills

Desirable Qualities

Methodical, accurate, technically minded, good organisational skills, exhibit high level innovation and motivation, high attention to detail, team player, conscientious, energetic, good time management and ability to work under pressure.

Responsibilities and Duties

- Machine configuration as per SOP

- Compiling of routine reports in RBMView

- Compiling bi-annual Management report

- Collection of data for Analysis

- Vibration Analysis, Alignment, Balancing, Thermography, Motor Current Analysis and Oil Sampling

Availability: The successful candidate must be able to start in their position as soon as possible.

Only CV’s sent to This email address is being protected from spambots. You need JavaScript enabled to view it. will be considered.

Applications close on 26th January 2018. If you have not received a response by 7th February 2018, please consider your application as being unsuccessful.

__________________________________________________________________________________

Vibration Technician

Witbank

Main Job Functions

- Responsible to plan, supervise and undertake work related to the providing of a professional CBM service to RS Division Witbank customers

- To undertake and ensure that all CBM services and work are carried out according to Company policies and procedures

- Ensuring that Failure Analyses are carried out on equipment tested and providing the Customer Action and Recommendation Report

Minimum Requirements

- National Electrical/Mechanical Certificate N3

- ISO 18436 Level 2 Vibration

- More than 4 years experience

- Intermediate Computer Skills

Desirable Qualities

Methodical, accurate, technically minded, good organisational skills, exhibit high level innovation and motivation, high attention to detail, team player, conscientious, energetic, good time management and ability to work under pressure.

Responsibilities and Duties

- Machine configuration as per SOP

- Compiling of routine reports in RBMView

- Compiling bi-annual Management report

- Collection of data for Analysis

- Alignment, Balancing, Thermography, Motor Current Analysis and Oil Sampling

Availability: The successful candidate must be able to start in their position as soon as possible.

Only CV’s sent to This email address is being protected from spambots. You need JavaScript enabled to view it. will be considered.

Applications close on 26th January 2018. If you have not received a response by 7th February 2018, please consider your application as being unsuccessful.

Updated version of condition monitoring app goes live

WearCheck’s revolutionary condition monitoring app - WearCheck Mobile - continues to be an increasingly popular choice among customers for communicating with WearCheck about sample results.

An updated version of the app was launched recently and offers several upgraded features, including better all-round usability and the ability to check the progress of a sample.

Once downloaded onto a mobile device, WearCheck Mobile gives customers highly enhanced access to critical information regarding machinery condition, allowing maintenance decisions to be made instantaneously, based on live data.

The app allows customers to access reports, view current samples list, and keep track of unread web/app reports. Notifications about items on this list are sent out as reminders. All data is highly secure, and is now even more nimbly accessible on the app with the “scroll to top” option.

One of the highlights and unique features of the app is the interactive key, where customers can ask a diagnostician about a specific sample, and receive an emailed reply on their mobile device.

Sample reports can be viewed on the mobile device as either one page (“concise”), or two page (“full”) pdf documents. Single or multiple pdf reports can be emailed to different recipients simultaneously. Sample reports can now be emailed from the equipment search tab.

Sample data can be submitted, either via the equipment/component search option (recommended), or via the “submit samples” option, where equipment/component verification is needed for currently-listed machinery. Where applicable, new equipment/components information is created in the WearCheck system. Customers can also view their five-day submission history.

Do you have questions or need help? Please contact WearCheck software support on This email address is being protected from spambots. You need JavaScript enabled to view it. or call (031) 700-5460.

YOU TALK... WE LISTEN!

Each year, we conduct a survey in which we ask our customers how we can improve, what works, what doesn’t work and so forth. Your feedback is invaluable to us. This shapes the way forward for us - determining the needs of our customers is critical to the direction our business takes in the future.

The 2017 customer survey produced a slew of compliments for WearCheck. Just some of the comments were:

‘Excellent service’

‘For the past 12 years, I have had no complaints . . . very happy [with] the way we do our reports and lube analyses reports’

‘Excellent technical support and advice given by Leon Marshall’

‘Happy and entirely satisfied’

‘Very good and helpful

‘Excellent service from staff’

‘All satisfied’

We have already instituted the suggestions for change and made adjustments to accommodate the constructive criticism. Thank you for your input.

As a token of our appreciation for the time taken to provide us with feedback, we award a prize to one lucky customer whose name is randomly drawn from survey respondents. This time round the lucky winner was Willem Britz of Assmang King Mine.

Lucky draw winner Willem Britz of Assmang King Mine is presented with his prize, a tablet worth R5 000, by WearCheck technical manager Steven Lumley. A prize is awarded annually to customer survey respondents.

Heart-warming help for youngsters

Every year, WearCheck Pinetown staff members open up their hearts – and their wallets – to bring some Christmas joy into the lives of the company’s long-term charity partner, the kids at St Vincent's orphanage.

St Vincent’s is based near Mariannhill, Durban, and houses over 100 homeless children.

Project co-ordinator Marvin Narainsamy, WearCheck’s foreign operations accountant, decided to do things differently this year. He outlines the plan, ‘’instead of giving the kids the usual gifts which can be short-lived, we decided to give the orphanage a gift that will entertain the children over a longer period of time.

‘We purchased them a 49" LED TV, a DVD player and a range of DVDs that will appeal to all age groups at the orphanage.

‘The house parents and children were so grateful and happy with this idea, as the orphanage did not have a TV up till now.’

In addition to this wonderful gift, the WearCheck team also provided the children with a delicious lunch, an ice cream treat and some groceries.

Says Marvin, ‘This would have not been possible without the valuable contributions made by the staff and then WearCheck matching these contributions – what a positive difference we have made in the lives of these deserving youngsters – thank you everybody!’

WearCheck at Windaba

The Windaba Expo in Cape Town never goes by without WearCheck being present at this well-attended annual wind technology event. Globally, countries are actively engaging alternative power sources than the traditional oil and coal options in a move to harness abundant natural resources and to be more earth-friendly.

The theme for this year’s Windaba conference was asset management which focused on optimising wind turbine life cycle through the use of remote online monitoring and data analytics.

For this year’s event, WearCheck showcased their specialist reliability solutions and newly expanded transformer services divisions with vibration, thermography and transformer oil analysis just been some of the services on offer as part of WearCheck’s condition monitoring portfolio for South Africa’s burgeoning wind industry.

Through a good condition monitoring programme, wind turbines are kept operating reliably at their peak output, enabling them to generate an uninterrupted power supply.

Standing by to shoot the breeze with Windaba delegates were WearCheck staffers, from left: Phillip Schutte, Steven Lumley, Des Rodel, Ian Gray and Sam Sublal