OIL LEVEL AFFECTS FOAMING

Before adding antifoam agents to get a handle on a foaming problem in a circulating system, one of the first things to check is the oil level. Both too much, and too little oil can lead to a foaming problem. Too much and there may be a piece of the machine touching the surface of the oil that shouldn’t, churning and slinging the oil (high-speed pinion in gearbox). Too little oil, and a vortex can form inside the reservoir at the inlet for the circulating pump, sucking in air. If you cannot tell the level due to the foam, you may be able to stick a clear piece of tubing straight down to the bottom of the reservoir. Cover the end of the tubing to create a seal and pull it out to observe the actual oil level. Don’t put anything into an oil reservoir unless you are certain of its internal configuration and components.

FIGHT DUST DAMAGE: PROTECT YOUR CRANKCASE!

Sources of solid contaminants in crankcase oils might include dirt and airborne dust, engine wear debris, rust, fuel soot and manufacturing or rebuild debris.

Road dust particles are typically harder than metallic wear particles and can cause far more abrasive damage and contact fatigue to interior machine surfaces than most other contaminants.

KINEMATIC VISCOSITY

Kinematic viscosity is a measure of a fluid's internal resistance to flow under gravitational forces. It is determined by measuring the time in seconds, required for a fixed volume of fluid to flow a known distance by gravity through a capillary within a calibrated viscometer at a closely controlled temperature.

THERMAL FAILURE IN LUBRICANTS

Lubricants can thermally degrade for a variety of reasons and causes. Unlike oxidation, thermal failure can occur in new lubricants with healthy additive packages. However, many of the symptoms of oxidation are also symptoms of thermal degradation. One of the most common causes of thermal failure in hydraulic fluids and some lubricating oils relates to aeration, i.e. entrained air bubbles. These bubbles can become rapidly compressed in hydraulic pumps and in the squeeze zones of bearings. This results in high localized temperatures. Hot surface carbonization is another form of thermal failure. When an oil thermally degrades, problems associated with sludge, varnish, deposits, viscosity change and additive decomposition will often occur.

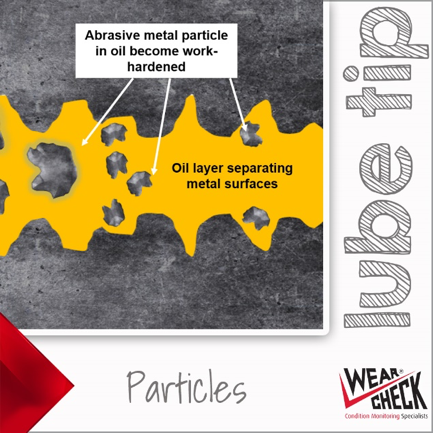

HOW PARTICLES CREATE MORE PARTICLES

Abrasive wear can cause a chain reaction in lubricated machinery. The typical chain reaction is: abrasive particles become work hardened, the work-hardened particles produce more particles, and then the new particles become work hardened. This chain reaction continues until the particles are removed by filtration or the machine fails.

BEWARE BLUE SMOKE!

KEEP OIL LEVELS IN CHECK

Low oil level is a serious cause of contamination in the hydraulic system. When the oil level is low, more air gets into the tank, and this often leads to destructive cavitation in the pump and to condensation on the tank walls, which generates sludge. Sludge decreases the lubricity of the oil, producing scoring and friction on surfaces with close tolerances.

THE IMPORTANCE OF OIL OXIDATION STABILITY

Oxidation stability is a chemical reaction that occurs with a combination of the lubricating oil and oxygen. The rate of oxidation is accelerated by high temperatures, water, acids and catalysts such as copper. The rate of oxidation increases with time. The service life of a lubricant is also reduced with increases in temperature. Oxidation will lead to an increase in the oil’s viscosity and deposits of varnish and sludge. The rate of oxidation is dependent on the quality and type of base oil as well as the additive package used.

AFTERMARKET OIL ADDITIVES CAN BACKFIRE

Increasing the percentage of a certain additive may improve one property of an oil, while at the same time degrade another. When the specified concentrations of additives become unbalanced, overall oil quality can be affected. Some additives compete with each other for the same space on a metal surface. If a high concentration of an anti-wear agent is added to the oil, the corrosion inhibitor may become less effective. The result may be an increase in corrosion-related problems.

HOW CONTAMINANTS AFFECT ADDITIVES

Particle contamination in a lubricating or hydraulic system is widely known as one of the most devastating contaminants. One effect of particle contamination that is rarely discussed is additive leaching. Many additives attach to particles and are removed, along with the particle, by filtration.

WATER ABSOPTION IN FLUIDS

The amount of water that a given fluid will absorb depends upon its base stock, viscosity, additive package, and temperature. The amount of water that can dissolve in a fluid is termed its saturation level. The saturation level for a hydraulic fluid is 200-300 ppm while for a lubricating oil it is around 500-600 ppm. Oil is cloudy when it is above its saturation level. The saturation level for a synthetic fluid is generally much higher than for a mineral base fluid.

NITRATION - WHY IT'S BAD

Nitration is the degradation of oil in the presence of nitrogen compounds. Nitration is a common mode of gas-engine lubricant degradation. It is a particular problem with higher temperature 4-cycle engines. Nitrogen oxides are typically formed during fuel combustion. These nitric oxides react with water to form nitric acid. The formation of nitric acids can lead to a corrosive environment to exposed engine surfaces. Nitration also leads to the formation of deposits and sludge.

UNDERSTANDING THE DIFFERENCE IN SYNTHETICS

There is no minimum quantity of synthetic base oil required in order to call a blend a semi-synthetic lubricant. Because Group III and Group IV base oils are both considered synthetics, any oil labelled as a full synthetic would contain either Group III or polyalphaolefin (PAO) or both. Any oil that is labelled as a partial synthetic, semi-synthetic or synthetic blend would contain Group I or Group II (mineral oil) plus some amount of Group III oil or PAO (synthetic).

THERMAL FAILURE IN LUBRICANTS

Lubricants can thermally degrade for a variety of reasons and causes. Unlike oxidation, thermal failure can occur in new lubricants with healthy additive packages. However, many of the symptoms of oxidation are also symptoms of thermal degradation.One of the most common causes of thermal failure in hydraulic fluids and some lubricating oils relates to aeration, i.e. entrained air bubbles. These bubbles can become rapidly compressed in hydraulic pumps and in the squeeze zones of bearings. This results in high localized temperatures. Hot surface carbonization is another form of thermal failure. When an oil thermally degrades, problems associated with sludge, varnish, deposits, viscosity change and additive decomposition will often occur.