Items filtered by date: Tuesday, 16 December 2025

WearCheck Spain hosts IWCG

WearCheck Spain hosts IWCG

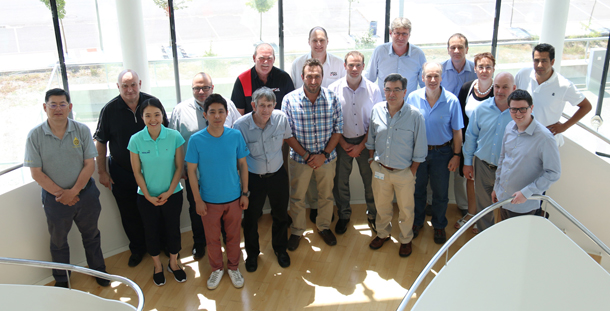

Each year, the International WearCheck Group (IWCG) members meet in a different member country to share ideas on the newest technology and condition monitoring advances, to meet with international suppliers, brainstorm and to keep the thriving business network going. This year, the group assembled in Pamplona, Spain in July.

These IWCG members gathered in Spain, from left to right: David Zau (China), Bill Quesnel Snr (Canada), Ha Jang (S. Korea), Bart Coen (Belgium), Tae Kim (S. Korea), Alistair Geach (Canada), Ken Hill (USA), Jon Fazenbaker (USA), Neil Robinson (South Africa), David Sharpe (UK), Jésus Terradillos (Spain), André Verlinden (Belgium), Esteban Lantos (Argentina), Akos Nemesnyik (Hungary), Barbara Monse (UK), Bill Quesnel Jnr (USA), Adam Cutler (UK) and Jorge Alarcon (Spain)

WearCheck now part of Torre Industries

WearCheck and our Set Point Group sister companies, have been acquired by Torre Industries, a dynamic JSE-listed industrial entity underpinned by strong brands and strong products.

The integration will have no negative impact on WearCheck customers, and the company will continue with normal operations, as will the other Set Point Group companies – Set Point Laboratories, Meter Systems, Letaba Group, Amis, Pneumax and RENG.

Says WearCheck managing director, Neil Robinson, ‘We are pleased to be part of Torre – a solid, well-renowned group in the industry, and one which shares WearCheck’s high standards of customer satisfaction, continued investment in technology, and ongoing staff training and education.

‘The integration process will be phased in over several months, and we will continue to keep you informed of any changes or improvements. We would like to reassure our customers that, as we are integrated into the Torre family, we are excited at the opportunities for development and growth that will evolve.’

Torre is an integral business in sectors such as mining, automotive, construction and industrial. The company has shown steady growth since its listing on the JSE in 2012.

Serving customers in selected high growth markets with the provision of equipment, parts, financing and support, Torre’s focus is the value added sale and rental of branded capital equipment, the distribution of high quality parts and components, the delivery of critical support services and the provision of financing solutions in support of their customers’ expansion programmes.

Torre’s business units include Parts and Components which has vast product and brand solutions for the automotive, commercial, off-highway and industrial sectors, as well as aftermarket repair parts and components for earthmoving equipment in the mining and construction sectors.

Torre Industries, technical tip, thermography and more…

The exciting news in this issue of Monitor is WearCheck’s integration with Torre Industries, our new holding company. Torre Industries is a key player in many of the industries in which WearCheck operates, and we look forward to the growth and development benefits that will evolve from this synergy.

Monitor 70 is bursting with useful information – you can now sign up for Mobius-accredited training via WearCheck, and learn about thermal imaging and its benefits, particle counting on diesel samples, as well as a discussion on gas engines and their merits.

Read all about this, and more, in the latest issue of Monitor. Click here to download WearCheck Monitor Issue 70.

World Cup fever hits WearCheck

Well, until now, WearCheck has been THE one-stop shop for condition monitoring, reliability solutions and checking the wear on components. And from today, you can also check something else that is critically important - the Rugby World Cup viewing schedule on the WearCheck website!

Just where is the final resting place for that much sought-after trophy, the Webb Ellis Cup, going to be for the next four years? Which country is going to stand proudly on the podium as the new World Cup champions? How are the beloved Springboks going to fare?

These are the burning questions on everyone’s lips at the moment. Don’t miss a match... click here to view our viewing schedule.

The big kick-off on 18th of September is drawing nearer by the day…

Go Bokke!

Bauma Africa 2015

Come and meet the WearCheck team at BAUMA 2015, which runs from 15 to 18 September at the Johannesburg Expo Centre. We will be at stand 35, Hall 7.

Our diagnosticians and reliability solutions technicians will be present to answer technical queries and explain the ins and outs of condition monitoring and how you can keep plant operating optimally through reliability solutions techniques.

And this year, we also invite you to look through a high-powered electrical microscope, witness an alignment rig in operation as it measures vibration, and experiment with a thermography camera.

How could thermography help you?

Well, some of the advantages of thermographic imaging are:

- Visual images can be stored for future reference and used for reporting functions

- It is not limited by the object’s component material. (ferrous, nonferrous, organic)

- It is a non-contact method of measuring temperature. In the majority of applications, it could be fatal if contact is made with the object where the temperature is measured.

- It is a non-destructive test method

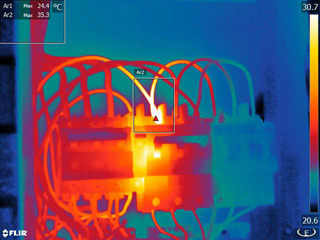

Some examples of thermal imaging done recently by WearCheck include monitoring a transformer cooling defect, paint batch plant motor scanning, kiln scan, electrical application where a major fire was prevented.

These are just some of the tools used by our technicians to ensure that you SAVE MONEY by avoiding catastrophic component failure and unplanned downtime.

Above: The bright yellow light in the centre of the image shows high temperatures on part of an electrical system, which, on subsequent inspection, was found to be a loose connection on the termination point.

CH4 can be worth so much more – (part two of two)

As the lifeblood of any mechanical system, oil performs many functions, such as reduction of wear, removal of contaminants, removal of heat and acting as a structural material.

Technical Bulletin 60 explored the various laboratory techniques for detecting abnormal wear and contaminants in gas engine oils.

In this edition, we examine what can be measured by oil analysis in terms of detecting oil degradation – both physical and chemical.

Gas engine oils must withstand various levels of oil degradation caused by the gas fuel combustion process, particularly where fuel quality varies significantly over time, such as gas engines running on biogas.

Condition monitoring techniques can facilitate effective maintenance of gas engines and support this emerging form of power generation.

We discuss the most widely used and OEM-requested laboratory techniques for detecting oil degradation, including kinematic viscosity, viscosity index, FTIR (fourier transform infrared), oxidation, nitration, total acid number (TAN), total base number (TBN), RULER (remaining useful life evaluation routine) and the new test, IPH (initial pH).

Interested in learning more? Then read Technical Bulletin 61 by clicking here.

WearCheck Middelburg gets new lease on life

WearCheck’s Middelburg facility has recently undergone a major revamp, and now boasts a spacious new laboratory with two sections – a dedicated ICP room and a main laboratory containing all the other instruments. The company also invested in new laboratory equipment that has increased sample turnaround time,

A brand new ICP (Inductively Coupled Plasma spectrometer) has been installed at the Middelburg laboratory, effectively doubling the laboratory’s capacity with the addition of this second ICP.

ICP spectrometry analysis provides high-speed detection and identification of trace elements at very low concentrations in oil to determine the levels of wear metals, contaminants and oil additives in lubricating oils.

WearCheck Middelburg also recently acquired a brand new generator. This helps to bypass any fallout caused by the current power crisis in the country, which has resulted in ongoing and unpredictable load shedding. This now means all of WearCheck’s laboratories have backup power supply, ensuring continuous uptime and uninterrupted service to our customers.

WearCheck Middelburg’s contact details remain the same: tel: (013) 246-2966 and physical address: Unit 7A, 13 Mandela Drive, Nungu Industrial Park, in Middelburg.

Laboratory supervisor Salisha Dhanasar operates the new ICP.

The WearCheck Middelburg team is proud of their brand new generator, which protects the laboratory equipment from interrupted power supply such as load shedding. They are, from left to right, Caven Selane, Sipho Magcaba, Rufus Mathekgane, Robinson Tshabalala, Salisha Dhanasar, Nelly Dlamini, Patience Skosana, Julia Motshwene and Randy Mathibela.

The beautiful new interior of WearCheck Middelburg’s laboratory.

The dedicated ICP laboratory at WearCheck Middelburg.

Minimise the power struggle with good condition monitoring

When preventive maintenance is not done regularly on machinery, it can lead to catastrophic component failure, which, in turn, can have a disastrous effect on a country’s power supply.

In 2008, more than 90% of South Africa’s electricity was produced from coal, with nuclear energy making up most of the balance. Growing energy demand and concerns over the environmental impact of coal-fired power generation has led to the diversification of South Africa’s energy portfolio through the incorporation of renewable energy technologies such as solar and wind power.

The generation of most types of energy uses machinery with moving components, such as wind turbines, and gas engines, all of which function optimally with a good condition monitoring programme in place.

WearCheck is THE one stop shop for condition monitoring and reliability solutions!

Come and find out more about our used oil analysis programme, including gas engine oil analysis, wind turbine analysis and even transformer oil analysis. WearCheck’s other condition monitoring services include vibration analysis, thermography, alignment and many more.

WearCheck will be at stand L15 at the Power Gen Africa Expo in Cape Town from 15 to 17 July. We invite you to come and discuss your technical queries with our team.

Mozambique Tete Mining Expo

Is your mining equipment operating at its peak potential? Do you have a reliable condition monitoring programme in place?

Come and get these answers and more at the WearCheck stand at the MTE Mining Exhibition in Tete, Mozambique on 3 and 4 June.

Our friendly staff members will be available to answer your technical queries and explain the full benefits of condition monitoring, including reliability solutions and oil analysis, and how investing in a good condition monitoring programme genuinely saves you money.

WearCheck’s Mozambique laboratory is based in Tete, and offers a range of condition monitoring services, including oil analysis, coolant testing and a 24 hour sample turnaround time. The laboratory opened nearly two years ago, and has been servicing the burgeoning local precious stone and coal mining industries.

WearCheck also operates a network of ten other laboratories around Africa.

Contact details:

t: +27 (0)31 700 5460

e: This email address is being protected from spambots. You need JavaScript enabled to view it.

w: www.wearcheck.co.za

Congratulations! The winner is…

We extend our hearty thanks to all the WearCheck customers who took the time to complete our recent survey. We had a record response rate this year, with nearly 200 completed survey questionnaires being filled in.

For the first time ever, it was possible to complete the questionnaire online – this has proved a popular option amongst our customers and we will be offering this again during our 2015 survey. This will be sent out to customers in August this year.

We sincerely do appreciate your feedback – it is via this forum that we can address any issues you raise and continuously improve our service – creating a win-win situation.

As a token of WearCheck’s gratitude to customers for taking the time to provide us with constructive criticism (as well as compliments!), a respondent’s name is randomly drawn from a hat to win a prize every year. This year, Fanie Prinsloo of Landrover Constantia Kloof won the lucky draw.

Customer survey 2014 lucky draw winner Fanie Prinsloo of Landrover Constantia Kloof (left) was awarded an Apple Ipad by WearCheck’s Phillip Croucamp.