Items filtered by date: Tuesday, 16 December 2025

New WearCheck Kitwe laboratory opens its doors

The official opening ceremony for WearCheck’s 6th world-class oil analysis laboratory - situated in Kitwe, Zambia - took place last month, and was attended by various key players in the mining, earth moving industry and petro-industries. Guests were treated to music, a sit down lunch and a detailed tour of the laboratory.

WearCheck managing director Neil Robinson praised the Kitwe laboratory project team at the launch. ‘The fact that the laboratory was able to process in excess of 1500 samples in the days before the official opening ceremony is testament to the demand for a reliable oil analysis service in the region, and we are grateful for the support from Zambian businesses.

The new state-of-the-art laboratory effectively doubles WearCheck’s Zambian presence as it joins the already successful laboratory at the Lumwana copper mine, both of which boast a 24-hour sample turnaround time.

Robinson added that a fuel and transformer oil testing laboratory will be introduced to the Kitwe laboratory later this year.

We wish the entire WearCheck Zambia team every success and congratulations on a great start - may you continue to grow from strength to strength!

WearCheck - a year in review

Despite difficult global trading circumstances, WearCheck enjoyed a successful and busy year in 2011 with lots of ‘firsts’ and other highlights, including many exciting new services and tailored tests, new laboratory instruments and a presence in several new countries.

Reliable, world-class oil analysis service from a highly experienced team is supported by state-of-the-art laboratory equipment and well-trained back-up staff. This, coupled with WearCheck’s structured expansion has seen the company show steady growth in both the domestic and international markets, entrenching its position as one of the global leaders in the oil analysis industry.

Some of the 2011 milestones are:

- A brand new, state-of-the-art Perkin Elmer gas chromatograph for determination of fuel dilution was installed in WearCheck’s Middelburg laboratory, bringing its analysis capabilities in line with WearCheck’s other laboratories.

- WearCheck entered the market in Namibia, with the opening of sales and support branches in Windhoek and Swakopmund.

- WearCheck's India laboratory was officially opened in July, expanding the WearCheck network from southern Africa to the Middle East and across to India. WearCheck India aims to service the burgeoning local wind turbine industry.

- The planning and groundwork for the January 2012 opening of WearCheck Kitwe progressed throughout 2011, culminating in the opening of our doors on the January the 20th.

- Each month, ongoing specialised staff training and upgrading of laboratory equipment took place, keeping WearCheck at the forefront of technological innovation.

- Service levels reached new heights with the launch of the first underground sampling facility for the mining industry, boosting WearCheck’s range of on-site sampling services. This was in conjunction with the expanded sampling service offered in the Steelpoort area with the purchase of a second vehicle and recruitment of additional sampling staff.

- Adding to WearCheck’s tailored product range of fluid analysis tests for specific industries was the introduction of the comprehensive and sophisticated heat transfer and turbine oil analysis kits.

- The online reporting system was formally introduced and has become increasingly popular, with many customers preferring this method of receiving their test results.

- WearCheck workers showed their hearts by partnering with the company in several community upliftment initiatives. During 2011, the children at St Vincent’s orphanage received gifts, treats and two wonderful parties, the U13 Highway soccer team sported new sponsored uniforms; and the education of 700 adults at the Thuto-Mfundo Adult Centre was boosted through the donation of a new computer laboratory and sewing machines.

- A daring team of WearCheck and Set Point staff took part in the popular, but daunting, 94.7 cycle race. All participants agreed that training and racing together was a great team-building exercise, and went a long way towards boosting fitness levels, improving motivation and setting and achieving goals.

- A feather in WearCheck’s cap, and further confirmation of their strong service excellence ethic, was having several SABS audits conducted throughout 2011 without any major findings.

- The annual WearCheck International (WCI) conference was hosted by WearCheck’s Pinetown branch in 2011. WCI members from seven countries met to discuss the latest oil analysis developments and share their experiences, technical research and skills.

- And a real achievement for 2011 is the increase in the number of samples processed per year - now in excess of 600 000 annually - a statistic that entrenches WearCheck’s position as the leaders in oil & fuel analysis!

Thank you and best wishes for the festive season

WearCheck Monitor 61

Why WearCheck?

WearCheck riders saddle up for 94.7 cycle race

An intrepid team of WearCheck staff, family members, and Set Point Group colleagues from around South Africa entered the popular, but daunting, 94.7 cycle race in Johannesburg last Sunday. Some of the team members gathered to show off their snazzy WearCheck-sponsored cycling kit just before the start of the race.

Among the finishers from the Pinetown laboratory were WearCheck MD Neil Robinson and lab manager Paul Swan, as well as sales developer Kay Meyrick. Finishing at the head of the pack in a flying time of 3hrs 17 minutes was Set Point Group CEO, Graham Horsfield.

All who participated agreed that training and racing together was a great team-building exercise, and went a long way towards boosting the cyclists’ fitness levels and the improved motivation of having set and achieved goals.

WearCheck’s world-class team of diagnosticians

WearCheck’s diagnostic team, who between them boast 125 collective years of oil analysis experience, successfully completed their International Council for Machinery & Lubrication (ICML) exams last year, and are now ICML certified for Level II Machinery Lubricant Analysis.

This certification is equivalent to category II of the ISO 18436-4 standard covering lubricant analysis for machine condition monitoring. It is directed toward advanced diagnostics and troubleshooting, integration with other technologies and programme management.

‘This internationally recognised certification reflects our ongoing quest for operational excellence, our policy of employing technical specialists of the highest calibre and our commitment to the advancement of our employees,’ said managing director, Neil Robinson.

WearCheck, a member of the Set Point Group, is the only oil analysis company in Africa to have ISO 9001 and ISO 14001 certification.

Photo: WearCheck’s ICML certified diagnosticians (front, from left) John Evans, Michelle Allis and Rowan Maartens and (back) Steven Lara-Lee Lumley, Ravi Chetty and Daan Burger. Absent: Quinton Verster.

Oil analysis prevents equipment failure for Atlantis Mining

Oil analysis by WearCheck Africa proved instrumental in avoiding machine failure on two of Middelburg mining contractor Atlantis Mining’s earthmoving units recently by detecting component wear in time.

All of the Middelburg-based mining contractors’ fleet Caterpillar, Komatsu, Hitachi, Volvo and Terex equipment have been on WearCheck’s oil analysis programme for the past 12 years.

On this occasion, one of the machines was a Caterpillar D9T bulldozer where samples on both final drives were diagnosed by WearCheck as borderline. The oil was resampled and drained but the samples came back as borderline again. Atlantis resampled the new oil after 100 hours in use and submitted this to WearCheck. Again the sample was borderline.

Critical sample

‘The misleading factor was that the magnetic plugs showed no signs of contamination,’ said Mark Johnstone, managing director of Atlantis Mining. ‘We continued to run the machine whilst monitoring the final drive oil samples until we were advised of a critical sample at 9028 hours. Again the magnetic plug showed no signs of contamination, but it was decided that the final drives should be opened.’

Machine failure avoided

Three weeks later the workshop removed the final drives at 9192 hours. On disassembly it was found that the inner bearing had started to ‘pit’ and that the wear was starting to go through the hard facing. All the bearings were replaced and a major failure was avoided.

‘This was thanks to our successful oil sampling programme, accurate diagnosis by Wearcheck technicians and timeous action,’ Johnstone said.

‘Knowing that we can rely on our oil analysis programme gives us peace of mind, particularly as we are working with machines that are costly to replace and where equipment downtime quickly eats into profits. It is a cost-effective conditioning monitoring tool that has proved its worth time and time again.’

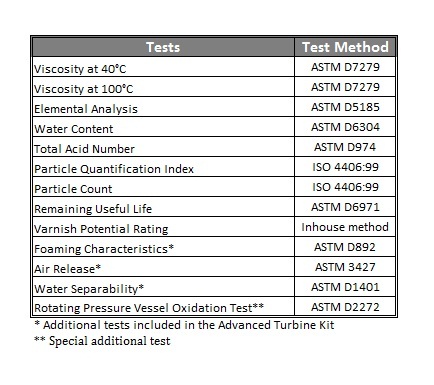

New product: Turbine Oil Analysis

The performance of the oil in a turbine application is vital in many aspects to ensure reliable performance of your turbine. WearCheck's Turbine Oil Analysis kits have been designed to measure the core functions of the oil and give you the ability to monitor the operating condition of the oil and hence conduct scheduled proactive maintenance procedures.

In today's world companies rely on turbines and compressors to provide power and gas transportation for core processes. Turbines and compressors already have demanding lubrication requirements and those demands are increasing. More demands are being put on these fluids as reservoir size and working clearances decrease and system power outputs, pressures, temperatures and oil service life increase. Lubricants must be highly oxidative and thermally stable to be able to handle operating temperatures. Additionally the lubricant must remain contaminant free to properly lubricate bearings and gears, and to act as a favourable hydraulic medium for governors and valving systems.

Oil oxidation and sludge will lead to sticking servo valves, meaning control valves will not open on demand. Oil contamination will accelerate wear, cause governors and valves to operate erratically and plug system filters. Unmonitored, poor oil condition leads to unplanned outages which are extremely expensive.

In order to achieve peace of mind on the operating condition of your turbine and compressor you need the comprehensive testing that WearCheck provides. Specifically designed for industrial turbines and compressors, WearCheck's Turbine Oil Analysis kit combines well established industrial tests with more recent advances in industry testing to provide an unparallel view of the operating condition of your critical lubricates.

WearCheck's Turbine Oil Analysis kit determines the levels of remaining antioxidants in the oil, detects for unwanted oil contamination and will accurately determine the suitability of the lubricant for continued use. A comprehensive diagnosis will warn you of any potential for damaging varnish build up and include recommendation for any necessary maintenance actions to remove contamination and restore the lubricant to optimum operating condition.

Tests include

Typical Applications

- Gas turbines

- Steam turbines

- Hydro-electric turbines

- Rotary compressors

For more infomation contact WearCheck on +27(0) 31 700 5460 This email address is being protected from spambots. You need JavaScript enabled to view it. or download brochure.

Technical Bulletin 52: How do oils degrade

Oils have a finite lifetime – they will eventually degrade and/or become contaminated, and will need to be changed. Lubricants consist of a base stock (mineral or synthetic) and an additive package. As oil works to lubricate a piece of machinery, the additives become depleted and deactivated, which eventually renders the oil inefficient.