Items filtered by date: Tuesday, 16 December 2025

Monitor Issue 63

WearCheck continues to lead the way in the condition monitoring sector, with innovations in several key areas. These include a brand new laboratory in Gauteng, a new reliability solutions division, new ISO 17025 accreditation, two new XRF spectrometers and even a new troubleshooting toolkit.

The latest bumper edition of WearCheck’s Monitor newsletter covers all these stories, as well as practical, hands on advice in the form of the latest lube tip, and an informative discussion on Base Number – a must-know on engine oils.

We introduce five new senior staff members, and cover all sorts of other WearCheck snippets.

As always, the latest training course schedules are available – remember to book your place early as courses do fill up quickly.

Heart warming tales

Once again WearCheck employees have reached deep into their own pockets to assist those in need. Inspired by East Coast Radio’s Winter Warmth campaign, WearCheck staff clubbed together and raised enough money to buy blankets for 200 needy people, who would otherwise have gone cold this winter.

And, thanks to the generosity of the WearCheck team, the orphans at St Vincent Children’s Home in Mariannhill were treated to a day of chocolatey Easter delights contributed by staff. Money was collected via a raffle, with WearCheck matching the money raised.

Francis Berner of WearCheck marketing explains that St Vincent’s is WearCheck’s charity of choice as it is located near their Westmead offices. ‘We believe it is important to reach out a neighbourly helping hand to our local community, to try and uplift those in need, especially the children.’

For both the blanket donation and Easter egg projects, all monies raised by employees were matched Rand for Rand by WearCheck, effectively doubling the efforts of the staff to reach out and help those in need.

Caption: Orphans at St Vincent’s Children’s with WearCheck employees Preshnie Govender (red shirt) and Charmaine Thumbiran (black waistcoat).

Caption: Francis Berner (right) of WearCheck marketing hands a cheque to East Coast Radio’s Darren Maule, as part of the radio station’s Winter Warmth Campaign.

Liquid Chromatography and its application in transformer oil analysis

In transformer operation, one of the key maintenance ‘musts’ is to ensure that the electrical system remains isolated through effective insulation. This is achieved through the use of special insulating paper (Kraft paper).

However, it is critical to monitor the paper’s tensile strength and degradation, or degree of polymerisation (DP) over time, to ensure that the paper continues to provide effective insulation for the transformer.

Analysis of the paper insulation, however, is a potentially dangerous, expensive and invasive procedure which requires the transformer to be taken out of service.

An alternative, quicker and easier method of testing the paper’s DP is by analysing the transformer oil.

How does analysis of the oil provide information on the paper’s degradation? The link is to be found via furanics, which dissolve in the transformer’s oil. It is generally accepted that the concentration of furanics can be directly related to the degree of polymerisation of the solid insulation in the transformer.

High performance liquid chromatography (HPLC) is a sophisticated analytical technique that is used to determine the degradation of transformer paper by analysing the concentration of furanics present in the transformer’s oil.

WearCheck’s latest Technical Bulletin (no. 54) features an explanation and in-depth discussion of HPLC, when it is used, why it is used, and how it works.

To view Technical Bulletin 54, click here.

Monitor 62

Monitor 62 - Industry icons, PQI, Lubmat and a one stop shop for lubricant analysis – news on all these and more can be found in the latest bumper edition of WearCheck’s Monitor newsletter.

The recent passing on of popular WearCheck founder Gary Brown, fondly known as ‘Mr WearCheck’, was a sad day for colleagues and customers alike – some of their tributes to Gary are featured in the Monitor.

Readers seeking technical tips will be rewarded with useful insight into turbine testing and a valuable explanation and discussion of the PQI (particle quantification index).

Also featured are WearCheck’s newest laboratory at Kitwe, Zambia; details of the next annual Lubmat conference in Spain; good advice on improving lubrication and WearCheck’s latest international quality certification.

The most up-to-date training course schedules are also included – remember, booking is essential as courses fill up very fast.

To view the latest Monitor, click here

Long term loyalty commended

60 years, or six decades – that’s the combined length of service given by two long-serving members of staff from WearCheck Pinetown. The important career milestones were celebrated recently by diagnostician Rowan Maartens (30 years) and accounts clerk Preleen “Pearl” Joseph (30 years).

Rowan joined WearCheck 30 years ago as a diagnostician, and since then has been hard at work as a key member of the diagnostics team. Says Rowan, ‘It’s been an interesting journey on a long road, very technical, and I have learnt so much along the way, both from colleagues and customers. I have really enjoyed it.’

Pearl spent her first 14 years with WearCheck as a lab assistant. Thereafter, she moved across to customer support and then accounts (first debtors, now creditors). ‘There is always something new every day, which keeps the job interesting, challenging and enjoyable,’ she says.

Managing director Neil Robinson congratulated Rowan and Pearl on reaching these incredible milestones. ‘We truly value your years of loyalty to the WearCheck family – not only do your years of experience benefit the company and your colleagues, but your familiarity with our customers and their needs translates into better customer service.’

Local mines give ‘thumbs up’ to on-site oil sampling service

Oil analysis specialists WearCheck’s on-site sampling has received a vote of confidence from the Mpumalanga Mining fraternity since the service’s introduction a year ago, with several large mines signing up.

Trained WearCheck technicians travel to the mines to take samples from mining machinery on site.

Customers have the option of either basing WearCheck personnel on their site, or WearCheck can provide daily sampling services to mines where the workload does not require a full- time mine employee to do the actual sampling.

During an intensive three month training course, the specialised sample technicians pass an obligatory “induction”, which qualifies them for sample collection, both underground and on machines that are brought to the surface for routine maintenance.

Once samples are taken, they are delivered directly to the nearest WearCheck laboratory for testing, analysis and diagnosis, and where necessary, clients are then alerted to potential machine component concerns.

Neil Robinson, managing director of WearCheck, believes that investing in this service saves mines time and money.

‘Historically, companies who invest in our oil analysis service have reported a return-on-investment ratio of approximately 1:10, with massive financial savings through the early detection of component wear, which in turn avoids costly, unscheduled downtime.’

‘By using our resources to do the sampling, it removes responsibility from the site engineer and his team, thus enabling our clients to remain focused on their core business, which is mining,” he said.

‘Another benefit is the increased consistency it brings to the sampling process by reducing the inevitable variables that occur when there are multiple “sample takers”, and this can assist in optimising the accuracy and validity of the analysis.

WearCheck’s Chis Hattingh, who provides operations/technical support for the on-site service in the region, takes up the story:

‘On one of our coal mine contracts, we invested in a specially-modified vehicle that complies with mining regulations. This vehicle is certified to navigate underground in a coal mine, collecting samples as per the mine maintenance schedule. Without the vehicle, the sample technician would be required to walk up to 8 kms to collect the samples.

‘Our technicians take samples from any mining machinery with oil-wetted components, including CMs (continuous miners), shuttle cars, roof bolters, feeder breakers, crushers, conveyor gearboxes, LHDs (load haul dumpers), tractors and stone dusters.

‘We are currently servicing several large mines, including BHP Billiton’s Khutala Mine and Samancor’s underground chrome mines. These include the Doornbosch, Lannex and Tweefontein sites.’

In addition to their mining focus, WearCheck provides on-site sampling service to a wide variety of industries, including oil refineries, sugar mills, aluminium mills, factories, process plants, paper mills and the petrochemical industry.

New troubleshooting toolkit detects problems

A new dimension to WearCheck’s traditional oil analysis service brings relief for customers with troublesome components, through the introduction of a mobile troubleshooting service.

Until recently, customers sent oil samples to WearCheck for analysis and diagnosis. A normal result meant operations continued uninterrupted.

However, reports indicating abnormal symptoms meant customers had to investigate and fix the source of the problem, which caused difficulties for operations without the necessary resources to conduct the repairs.

Now, a specially-trained WearCheck technician with a diagnostic toolkit can be called on-site to investigate, identify and evaluate problems.

Technical support consultant for WearCheck, Herman Geldenhuys, who developed the troubleshooting toolkit, explains, ‘Typical customer reactions to problematic reports were: “What do we do? How do we do it? We don't have the skills - the tools - the knowledge - we need help!” The mobile troubleshooting clinic evolved in response to these calls for help.

‘Our on-site diagnostic equipment identifies symptoms such as blow-by, low oil pressure, coolant leaks, crank shaft float, exhaust pressures and abnormal operating temperatures. An evaluation report then equips the customer’s technicians to isolate and rectify the faults.’

Geldenhuys believes the new service has additional benefits. ‘Prior to purchasing pre-owned equipment, WearCheck’s mobile troubleshooter can test, evaluate and verify the quality of the unit.

‘Furthermore, the troubleshooting service can determine the necessity (or not) of conducting costly periodic machine overhauls or re-builds.

Says Geldenhuys, ‘Sometimes, customers do not gain the true potential savings of an effective oil analysis program due to skills or equipment shortage. The new mobile troubleshooting service aims to address this, and take traditional diagnostic oil analysis to the next level by extending condition monitoring to incorporate an on-site repair dimension.’

For more information, please visit www.wearcheck.co.za, or call WearCheck on (011) 392-6322 or Herman Geldenhuys on 083 628-9404.

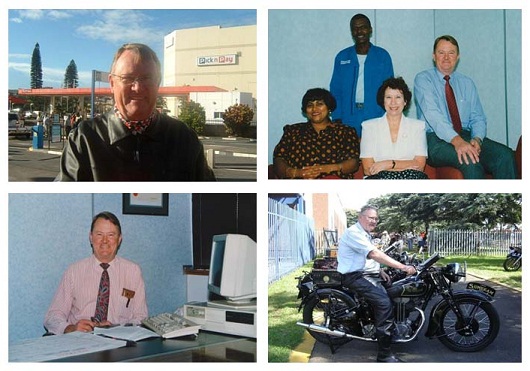

Gary Brown

It is with great sadness that I write to inform you of the passing of Gary Brown.

Gary passed away peacefully on Saturday the 3rd of March 2012 after losing his fight with cancer.

As most of you are aware, Gary was one of the founders of WearCheck nearly 40 years ago

and was responsible for creating the foundations on which the success of WearCheck stands today.

Bernard of Chartres used to say

Gary is survived by his wife Jenny, daughters Jill and Brigette, son Quentin and his five grandchildren.

I'm sure you will join me in sending our condolences to the Brown family at this sad time.

Neil Robinson

SOS: Sources of Silicon

The presence of silicon, its compounds or its alloys in lubricants has long been considered an indicator of wear and / or contamination. However, this can be misleading.

For an accurate understanding of the implications of the detection of silicon in oil, it is essential that the interpretation of oil analysis results is conducted holistically, and all results are diagnosed in relation to each other by highly skilled and experienced diagnosticians.

In the latest Technical Bulletin, WearCheck’s Diagnostic Manager John Evans discusses the various sources of silicon and what it means when present in oil.

Super 15 viewing schedule

The 2012 Super 15 rugby tournament kicks off in just 3 days!

Make sure you don’t miss your team playing by downloading the WearCheck Viewing Schedule which highlights all the matches and times taking place over the 24 week long tournament.