Items filtered by date: Tuesday, 16 December 2025

The Monitor newsletter is published!

The latest WearCheck Monitor newsletter features our Festive Season opening hours, along with interesting discussions about the role of AI in machinery maintenance, lubricant sampling valves, the new Lubrigard website and Adblue.

The customer survey lucky draw winner is announced, we offer you some transformer tips and a lube tip, and we share some heartwarming stories about our social responsibility programme – WeCare.

You can plan your team’s training courses for 2026 – our full training calendar is included in the newsletter.

You can read Monitor 98 here: https://www.wearcheck.co.za/shared/M98.pdf

WHY AI WILL NEVER TRULY UNDERSTAND MACHINES — AND WHY THAT MATTERS

By Annemie Willer, manager WearCheck ARC Division

Cutting-edge technology and solutions powered by artificial intelligence (AI) are embraced by WearCheck, where the extreme accuracy of data used to assess and diagnose machine health is paramount.

However, it is important that certain diagnostic responsibilities are not just assigned to AI tools without considering the need for human intervention and experience.

We keep hearing worrying claims from industry stakeholders and customers that if you throw enough data from vibration, oil, thermography, process sensors, ultrasound, and AE (acoustic emission) into an AI system, it’ll somehow converge into a perfect picture of machine health, complete with the exact corrective action to take.

It’s a nice idea. In fact, it sounds like the future. But I don’t buy it.

Importantly, this is not because I’m anti-technology — quite the opposite, in fact. I’ve worked in diagnostics long enough to see the value of every tool we have. But I’ve also been around long enough to know this: machines don’t behave according to theory. And AI doesn’t understand that.

For example, I keep encountering the myth of “convergence” — the idea that all condition monitoring technologies can fuse into one holistic truth, which assumes that machines behave in predictable, repeatable ways.

But they don’t.

You can install ten pumps from the same OEM, running under the same process conditions, in the same plant, with the same lube, and still... they won’t age the same. One might run clean for six years. Another might seize up in eight months. And no amount of sensor data is going to tell you why - not reliably.

Why? Because machines are not clones. They're flawed. They are manufactured to tolerance, not perfection. Machined surfaces differ microscopically, and assembly is never identical. And once you add human hands, production targets, rushed shutdowns, and midnight shift decisions into the mix — good luck feeding that into an algorithm!

It is important to take the real-world situation into account when assessing an asset. AI relies on data, but data only captures what the sensors see — not what the human maintainer did when nobody was watching. It does not record the subtle looseness that a technician "felt" but didn’t log. It does not register the fact that someone topped up the wrong grease, or skipped torque checks, or ran a fan uncoupled for three minutes at startup.

No historian records that. And without that real-world information, AI is flying blind on the stuff that actually causes most failures.

I believe that every condition monitoring technology has its place — and its limits. For example, vibration monitoring tells us about mechanical behaviour; oil analysis identifies lubricant condition and contamination; thermography picks up heat and load imbalance, AE and ultrasound testing give early warnings of friction, turbulence, or sparking; and process data provides the operating context — but not the root cause of failure.

These monitoring techniques and their test results don’t converge neatly. They weren’t designed to. One doesn’t combine them to get a better truth — rather, they should be compared to demonstrate different perspectives. That’s what makes condition monitoring powerful: it’s a team effort, not a solo act.

Can we rely on AI?

AI is useful, just not the way that the vendors keep claiming. It can spot changes over time. It can rank the risks, it can filter out noise and highlight anomalies - all of this is valuable.

Importantly, however, AI cannot know the history of every shaft and housing. It cannot understand why a lube change worked for one gearbox and not the next.

It cannot interpret subtle mechanical behaviour that only a human technician would notice, and it cannot predict how different people on different shifts handle the same piece of equipment.

In other words — AI can help one find where to look, but not what to do when you get there.

I have always told our customers that machines are messy, and that this is not a problem, it is merely the reality. Here’s the truth: machines have personalities. Not literally, of course, but in how they wear, respond, and behave under pressure. And a lot of that has nothing to do with engineering design or process control. It has to do with maintenance history, human touch, and physical realities that no AI-powered model — however sophisticated — can learn.

The idea that AI will converge all technologies into one correct decision ignores this complexity. It reduces the craft of diagnostics to a logic problem, when in truth, it’s part science, part art, and always tied to context.

Let AI support us. Let it help us scale, see patterns, and work smarter. But let’s stop pretending it can replace understanding — or diagnose machines like a seasoned engineer can. Because machines don’t live in the cloud. They live in the real world. And in the real world, convergence isn’t the goal. Clarity is!

KEEPING IT REAL – WEARCHECK’S ONGOING COMMITMENT TO GENUINE QUALITY

In a world where deepfakes and fake claims blur the line between real and manufactured, authenticity matters more than ever. That’s why this November – World Quality Month – WearCheck is proudly reaffirming its commitment to real, verifiable quality.

For us, quality isn’t a buzzword. It’s the everyday standard that defines how we work — from the rigour of our scientific laboratory methods to the professionalism of our customer service.

A Legacy of Trust, Built on Certification

Our recent re-certification to ISO 9001:2015 by the South African Bureau of Standards (SABS) reinforces this commitment. WearCheck first earned ISO 9001 certification back in 1996, and added ISO 14001 in 2005. Every year, we undergo surveillance audits and, every three years, a full re-certification. It’s not a tick-box exercise — it’s how we keep our systems robust, our processes consistent, and our team focused on continual improvement.

As our Quality Administrator, Prinda Narasi, puts it:

“Our customers, especially fleet operators, rely on us for results they can trust. ISO 9001:2015 is independent confirmation that our systems are sound and our culture is built around quality. In a time when manipulated content can cloud judgment, verifiable, third-party certification helps customers separate marketing claims from proven capability.”

Why It Matters

For the transport sector, ISO 9001:2015 means dependable turnaround times, a right-first-time mindset, and clear, actionable reporting. It ensures every oil, fuel or coolant sample analysed by our team provides accurate, timely insights — the kind that support better maintenance decisions and longer equipment life.

Transparency Builds Trust

We always encourage our customers to verify supplier certifications. It’s easy to do: simply check with the issuing certification body or its online directory. Sadly, non-genuine certificates are not uncommon across industries. At WearCheck, we welcome verification — because transparency is part of the trust.

Quality Is How We Work

Our quality system isn’t something we “dust off” once a year. It’s alive and active — driven by internal audits, management reviews, risk-based thinking, and ongoing staff development. It’s this continuous focus that ensures consistent, reliable results in our laboratories and responsive support for our customers.

For nearly three decades, WearCheck has maintained multiple international quality confirmations, including ISO 9001:2015, ISO 14001:2015, and ISO/IEC 17025:2017. We’ve never failed a renewal — and we don’t plan to start now.

Because when we say quality, we mean real quality — delivered by real people, using real science, for real results.

Precision in every drop – powered by ICP technology

Inductively Coupled Plasma – Optical Emission Spectroscopy (ICP-OES) turns a small oil sample into clear maintenance intelligence. The sample is nebulised into an argon plasma, where atoms are excited and then emit light at element-specific wavelengths in the UV/visible range. The intensity at those wavelengths is proportional to concentration, which means that metals and additives can be quantified precisely against calibration curves.

In the latest high-tech ICP instruments at WearCheck, modern Echelle optics with CCD/CID detectors capture many wavelengths at once, enabling fast, simultaneous multi-element analysis with excellent sensitivity and selectivity. Rigorous calibration underpins accuracy: certified reference materials, tight linearity (very high R² values), daily calibration checks, scheduled services and periodic method validation keep results reliable across different lubricant types.

High-throughput autosamplers enable us to process 100+ samples per hour, with multiple rapid reads per sample to strengthen precision. Automated quality controls pause analysis if anything falls out of spec. Aligned to recognised methods (such as ASTM D5185), this approach provides consistent insight into additive health, contamination and component wear, helping teams decide if oil is fit for service, spot abnormal wear early and plan interventions before minor issues become failures. In short, WearCheck offers faster turnaround, lower detection limits and data you can trust.

For a deep-dive into our ICP offerings, you can read our latest Technical Bulletin 94, which can be downloaded here.

Our latest Monitor newsletter is ready!

Dissolved gas analysis, rheology, advanced legionella testing, top transformer tips and even a chance to win a prize worth R6,000 – these are just some of the stories featured in the latest WearCheck Monitor newsletter.

We also bring you news of international and local expos and conferences where WearCheck was present, and a heartwarming story about some very special blankets, which were knitted by one group of grannies and donated to another group of grannies.

Technical training for maintenance staff is an investment which yields excellent returns. Check out our latest schedule of upcoming customer training courses, which focus on more than 12 different areas of condition monitoring.

You can read Monitor 97 here: WearCheck Monitor 97

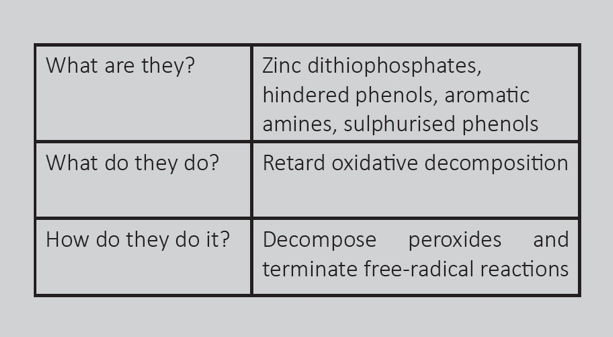

ANTIOXIDANT ADDITIVES – the anti-ageing additive in your oil

Calling all pop quiz hot shots - what do blueberries, a jar of the most expensive face cream in the world and a drum of new engine oil have in common? They are all jam packed with oxidation inhibitors, or antioxidants, as they are also known.

In this instalment of the lube series, we are going to unpack the oxidation process and explore how antioxidants keep your oil young at heart.

Oxidation is perhaps the most common chemical reaction, not just in lubricant chemistry, but also in everyday life. Oxidation reactions take place during the combustion of fuel, when metal surfaces rust, when cleaning wounds with hydrogen peroxide and even when a cut apple turns brown.

|

Here’s a bit of trivia - once exposed to oxygen, enzymes in your apple begin converting natural chemicals called polyphenols into melanin that gives the flesh a brown, rusty colour. In a nutshell, oxidation is the loss of electrons or the increase in oxidation state of a molecule, atom, or ion in a chemical reaction. When it comes to lubricating oils, oxidation results in the sequential addition of oxygen to the base oil molecules, producing a number of different chemical species, including aldehydes, ketones, hydro-peroxides and carboxylic acids. Oxidation is the primary cause of oil degradation, and it occurs at all temperatures, but is accelerated at higher temperatures. Like many chemical reactions, oxidation rates increase exponentially with increasing temperature due to the Arrehenius rate rule. For most mineral oils, a general rule of thumb is that the rate of oxidation doubles for every 10°C increase in temperature above 75°C. Oxidation is further accelerated by the presence of contaminants like water, and wear metals like iron and copper, which act as catalysts. Oxidation in lubricants takes place through a complex series of chain reactions that consists of three key stages - initiation, propagation and termination. |

|

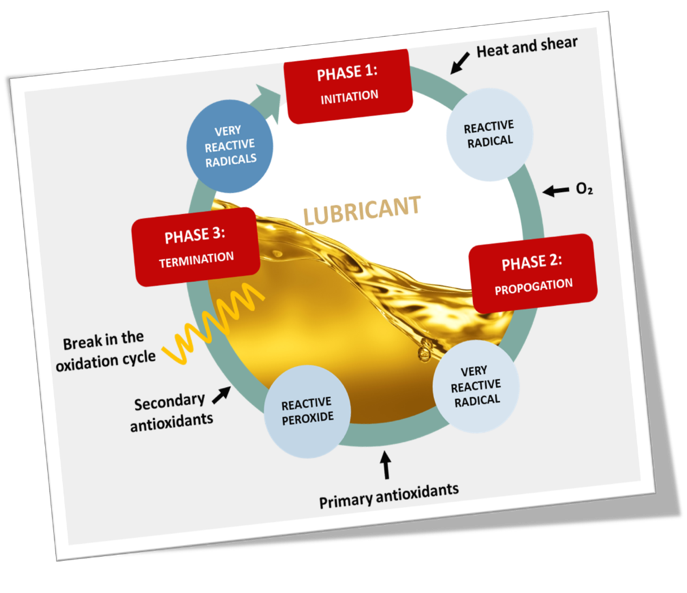

In the initiation stage, one of the external factors (temperature, contaminants, wear metals etc) causes a free radical (or unpaired electron) to be generated in one of the organic species that is part of the lubricant. This process involves breaking a bond with a hydrogen atom.

The free radical is a highly reactive species that can react with oxygen to form a peroxide radical, that can generate additional radicals through reaction with more components in the lubricant. This step is known as propagation and leads to further decomposition of the lubricant.

Eventually two of the radical species combine and form a stable compound. This is the termination step, because it removes free radicals from the system. However, the termination step is only effective in stopping the process if no more free radicals are formed during initiation.

In terms of its effects, oxidation typically results in impaired chemical and physical properties of the base oil and additives – increases in viscosity and organic acids, the formation of sludge and varnish, additive depletion - all of which, in turn, will have a detrimental effect on the system being lubricated.

It stands to reason that improving oxidation resistance is critical to improving lubricant stability and the operational life of the lubricant which, in turn, allows for extended oil drain intervals.

So, now for the start of the show. Antioxidants are used to extend the operating life of your lubricant, and these days, nearly all lubricant formulations contain some kind of oxidation inhibitor in some concentration.

They function by interrupting the three-step oxidation process either through reaction with free radicals or decomposing peroxide radicals.

There are two main types known as primary and secondary antioxidants. The former inhibits oxidation by reacting with chain-propagating free radicals to form stable molecules. Primary antioxidants are basically free radical scavengers made from compounds like aromatic amines and hindered phenols.

The latter, secondary antioxidants, are peroxide decomposers that consume unstable hydrogen peroxides to form stable alcohols. It is for this reason that secondary antioxidants are also known as peroxide decomposers. These peroxide decomposers are made from phosphorus- and sulphur -containing compounds that include sulphides, phosphates and - my personal favourite - zinc dialkyldithiophosphates, or ZDDPs.

Besides functioning as an antioxidant, ZDDPs are also a very effective anti-wear agents in many applications. ZDDPs have been a mainstay of diesel engine oil formulation and performance for over 60 years, and with good reason – no single additive provides the same benefit as cost effectively as ZDDPs.

However, The Times, They Are a-Changin’. With new engine designs and the addition of emission-control technologies, come changes to oil formulations and, needless to say, additive selection.

With the restriction in phosphorus-containing additives like ZDDPs and increased oxidation-control requirements, formulators are increasingly turning to incorporating higher levels of ashless antioxidants in their blends. Adieu ZDDPs!

WEARCHECK WATER EARNS ACCREDITATION FOR MICROBIOLOGICAL TESTING

Great news from the WearCheck Water team — our Johannesburg lab has just earned ISO/IEC 17025 accreditation for testing Total Coliforms and E. coli in water. This follows a detailed audit process and adds another feather to our cap when it comes to delivering top-quality testing services.

What It Means for Our Customers

This new accreditation gives our clients — both in South Africa and beyond — even more confidence in the work we do. It proves our team is working to the highest international standards when it comes to microbiological testing.

WearCheck Water is part of WearCheck, a specialist condition monitoring company. We’re proud to be the only oil analysis company in Africa with ISO 9001 (quality), ISO 14001 (environmental), and ISO/IEC 17025 (lab quality) certifications — and now our water division is even stronger with this latest win. We also recently received SANAS accreditation for testing AdBlue®/DEF (diesel exhaust fluid).

Why This Testing Matters

General Manager of WearCheck Water, Thelma Horsfield, explains:

“It takes months of hard work to develop the testing method and get it up to standard for SANAS approval. This accreditation confirms our lab’s ability to carry out precise and reliable water-quality testing.”

The method we use — membrane filtration — is a well-respected technique in water testing. It helps us identify and count total coliforms and E. coli in water samples.

Coliforms are bacteria often found in soil, plants, and surface water. Most are harmless, but their presence in drinking water could signal other dangerous contaminants. E. coli is a specific type of coliform found in the intestines of warm-blooded animals, and some strains can cause serious illness — so accurate detection is crucial for public health.

Celebrating Our People

A big shout-out goes to our lab assistant Khensani Mbuli, who played a key role in securing this accreditation. Thanks to her dedication and skill, she’s now been appointed an ISO/IEC 17025 Technical Signatory — a huge achievement in the world of lab testing!

Thelma explains: “Becoming a Technical Signatory is no small task. It takes deep knowledge, hands-on experience, and loads of training. TSs have the final say when it comes to signing off test results, so it’s a position of real trust and responsibility.”

Khensani joins six other senior Technical Signatories in our team: Moses Lelaka, Thelma Horsfield, Lerato Letsoalo, Lorato Hotane (our nominated rep), Katlego Mokoroane, and Michelle Wium.

Supporting a Range of Industries

WearCheck Water offers professional water analysis services across a variety of sectors — from mining and agriculture to manufacturing and fleet management. This latest accreditation is just one more way we’re proving our commitment to quality, reliability, and keeping water safe.

Crude awakening – part 1 of 4

You’re in for a ‘crude awakening’ when you download WearCheck’s latest Technical Bulletin! You will be treated to an in-depth explanation of the processes of producing oil, fuel and other petrochemical wonders that power our modern lifestyle. The epic tale about this almost magical process begins with the formation of the crude oil millions of years ago, and flows through all the stages of extracting, distilling, cracking, coking, refining and blending it into consumer-friendly products.

If you’d like to join us as we explore the molecular magic and unpack the chemistry behind crude oil, please download Technical Bulletin 92 here.

SAMPLING TINS AND BEST PRACTICES IN TRANSFORMER OIL ANALYSIS

Transformer oil analysis is a crucial aspect of electrical maintenance, ensuring the reliability and efficiency of oil-filled electrical equipment. However, the accuracy of this analysis begins long before the laboratory testing process—it starts with proper sampling. The choice of container and adherence to best practices play a significant role in obtaining reliable results.

The Importance of Proper Sampling

Laboratories follow strict procedures and standards to maintain compliance with industry certifications and requirements. However, even the most advanced laboratory can only provide accurate results based on the quality of the sample it receives. If a sample is taken incorrectly, stored improperly, or collected in a contaminated container, the results may be compromised. This can lead to incorrect diagnoses and costly maintenance decisions.

Recommended Sampling Containers

In South Africa, the standard container for transformer oil sampling is a one-liter tin. However, alternative containers may be used under specific circumstances:

1. Glass Bottles

Certain mining operations require the use of clear glass bottles for security reasons. While glass is suitable for sampling, it presents safety risks due to its fragility. Breakage during transport or handling can pose hazards to both field personnel and laboratory staff.

2. Plastic Containers

Plastic containers are generally discouraged because they can interfere with most laboratory tests. However, they are acceptable for Polychlorinated Biphenyls (PCB) analysis. For this purpose, WearCheck provides 100 ml single-use plastic bottles, which are responsibly discarded after testing to ensure environmental compliance.

3. Gas-Tight Syringes

For Dissolved Gas Analysis (DGA), gas-tight syringes offer excellent repeatability, particularly for transformers with high gas levels, such as those in wind and solar farms. However, these syringes hold only 30 or 50 ml of oil—insufficient for comprehensive testing—and are more expensive than tins. They are also fragile and prone to breaking during sampling, transport, or handling in the laboratory.

Why New Tins Matter

WearCheck strongly recommends using new tins for each sample. While this increases sampling costs, it helps prevent contamination-related issues. A recent case study illustrates the risks of reusing tins: a client noticed a slight increase in PCB values, which was traced back to a second-hand tin. The history of reused tins is often unknown, and residual contaminants can skew moisture and dielectric readings. This can lead to unnecessary oil purification or replacement, costing clients significant amounts of money.

Best Practices for Transformer Oil Sampling

To ensure accurate results, the sampling process must be conducted with precision. Here are some key best practices:

1. Clean the Sampling Container with Transformer Oil

A client in the Northern Cape reported finding water in the flanges from which samples were taken. This underscores the importance of flushing the sampling container with oil from the transformer to remove potential contaminants.

2. Avoid Reusing Sampling Tubes

Residual water or PCB contamination from previously used sampling tubes can compromise results. Clients should work with reputable service providers who follow stringent protocols to prevent cross-contamination.

3. Rely on Trained Technicians

Improper sampling techniques, even minor mistakes, can lead to incorrect diagnoses and costly consequences. Engaging trained professionals ensures that samples are taken correctly, stored properly, and handled according to industry best practices.

Conclusion

Proper sampling is the foundation of accurate transformer oil analysis. By using the correct containers, maintaining cleanliness, and ensuring trained professionals conduct the sampling, clients can trust the integrity of their oil analysis results. Cutting corners in the sampling process can lead to misdiagnoses, unnecessary maintenance, and financial losses. Investing in proper sampling practices is an essential step toward effective transformer maintenance and long-term operational reliability.

ADBLUE AND ACCREDITATION: WHY IT MATTERS?

At WearCheck, we’re thrilled to share some exciting news—our Water division has become the first laboratory in Africa to achieve ISO17025 accreditation for testing AdBlue®/DEF (Diesel Exhaust Fluid)! This certification, granted by the South African National Accreditation System (SANAS), is a major milestone that reinforces our commitment to quality and precision.

Why Is Accreditation Important?

Accreditation isn’t just a fancy certificate on the wall—it’s proof that a laboratory meets strict international standards. With this new ISO17025 accreditation, WearCheck can now officially test AdBlue®/DEF to ensure manufacturers meet the ISO 22241 requirements. This is essential for AdBlue® producers, fleet managers, fuel depots, and original equipment manufacturers (OEMs) who rely on high-quality DEF to keep their diesel engines running cleanly and efficiently.

What Is AdBlue® and Why Does It Matter?

AdBlue® (also known as DEF) is a key player in reducing vehicle emissions. It’s a non-toxic, colorless liquid made of 32.5% high-purity urea and de-mineralized water. When injected into the exhaust system of vehicles with Selective Catalytic Reduction (SCR) technology, it helps break down harmful nitrogen oxides (NOx) into harmless nitrogen and water vapor. The result? Cleaner emissions and a healthier environment.

The Science Behind AdBlue®

Vehicles with SCR technology have a separate AdBlue® tank, which feeds the fluid into the exhaust stream. When heated, AdBlue® decomposes into ammonia and carbon dioxide. This ammonia reacts with NOx in the catalyst, converting it into nitrogen and water—substantially reducing air pollution. But for this process to work efficiently, AdBlue® must be produced to exacting ISO 22241 standards, ensuring it doesn’t harm engines or emission systems.

How WearCheck Ensures AdBlue® Quality

At our Johannesburg laboratory, we conduct a range of tests to verify AdBlue® quality, including:

- Titrimetric Testing: Checking alkalinity levels.

- Gravimetric Testing: Identifying insoluble matter.

- Colorimetric Testing: Measuring biuret and aldehyde content.

- Ionisation Testing: Detecting metal contamination.

We’ve also invested in a state-of-the-art refractometer to enhance our testing capabilities. And soon, we’ll be expanding this service to our Cape Town laboratory!

How to Take a Proper AdBlue® Sample

- To get an accurate test result, sampling must be done correctly. Here are some tips:

- Use only high-density polyethylene (HDPE) or stainless steel containers.

- Ensure containers are free from chemical residues—rinse them with distilled or deionized water before use.

- Take a representative sample—avoid areas with sediment or contamination.

- Flush the sampling point by allowing a few liters to flow out before collecting the sample.

- Seal and label the container properly, then store it in a cool, dry place until testing.

Need Your AdBlue® Tested?

If you manufacture, distribute, or rely on AdBlue®, WearCheck’s analysis services ensure that your product meets ISO 22241 standards. Contact us today to learn more!

Visit: www.wearcheck.co.za / Call: (021) 001 2100/ Email: This email address is being protected from spambots. You need JavaScript enabled to view it..

Stay ahead with WearCheck—your trusted partner in fluid analysis!