Items filtered by date: Tuesday, 16 December 2025

Biodiesel: A complex minefield

The subject of biofuel is vast and often controversial, and very topical right now as the world seeks more sustainable fuel sources. A practical and strategic approach to biodiesel is the thinking in what follows. Need, greed, legislation, climate change, deforestation, fake news, opportunism, ignorance, oil price, and a lack of long-term thinking all go into the melting pot of biofuel debates.

Biofuels are energy sources made from recently-grown biomass (plant or animal matter). Biofuels have been around for a long time, but petroleum and coal have been used primarily as energy sources due to their high abundance, high energy value, and cheap prices. Fossil fuels such as coal and petroleum also come from biomass, but the difference is that they took millions of years to produce.

To read the full article in our Technical Bulletin 74, please click here to download.

WearCheck provides a seamless service during SA disruptions

More CPD points, prize winner, Guinea lab, Indian Navy and so much MORE!

Our latest issue of Monitor newsletter is hot off the press! We share plenty of good news – for example, WearCheck’s oil analysis courses are now accredited to earn CPD points for delegates, an educational discussion on pour-point depressants, some insight into diesel engine oil consumption, and both oil analysis and reliability solutions training courses are now available in Kenya. Stories on recycling, supporting the Air Mercy Service and labs supporting each other in times of crisis will warm your heart. You can view our 2021 training schedule to put your upskilling plan into action.

Diesel emissions – a breath of fresh air – part two

We continue our discussion around reducing air pollution through stricter diesel engine emission standards and techniques. In this Technical Bulletin - the second of a two-part series – we examine the intricacies of appropriate lubricant viscosity as well as the performance criteria of a range of additives and how they contribute to the war against harmful emissions, or not.

In Technical Bulletin 72, we looked at the various diesel emissions produced, the laws governing them, and the technologies utilised to limit these emissions in mitigation of green-house gases and the pursuit of better air quality. Now, we look at how all these developments will change the appetite of the diesel engine.

Technical Bulletin 73 is only available in the digital version. You can download it for free here.

Diesel emissions – a breath of fresh air

As global consciousness around pollution grows, and the reduction of pollution becomes legislated in more and more countries, this has a direct impact on engine manufacturers and operators – some of the primary producers of air pollution.

In this Technical Bulletin (the first of a two-part series) we discuss various engine emission standards around the world, what emission-reducing strategies can be implemented, which ones work effectively, and why.

Technical Bulletin 72 is only available in the digital version. You can download it for free here.

TOOLBOX TALK: FILTER ANALYSIS

Oil analysis is able to monitor the health of the lubricant, the health of the machine and levels of contamination through a series of chemical and physical tests. However, it is a snapshot in time of these three parameters. It lets you know what was going on at the time the sample was taken – sometimes more information is required.

Oil filters contain wear and contamination debris that has built up over time, it is like a diary of what has happened to the component since the filter was last changed. The filter can contain debris that is too large to circulate in the oil and would not necessarily show up in traditional oil analysis. It is also effective where large sump volumes may mean that wear and debris are too diluted to be detected at useful levels.

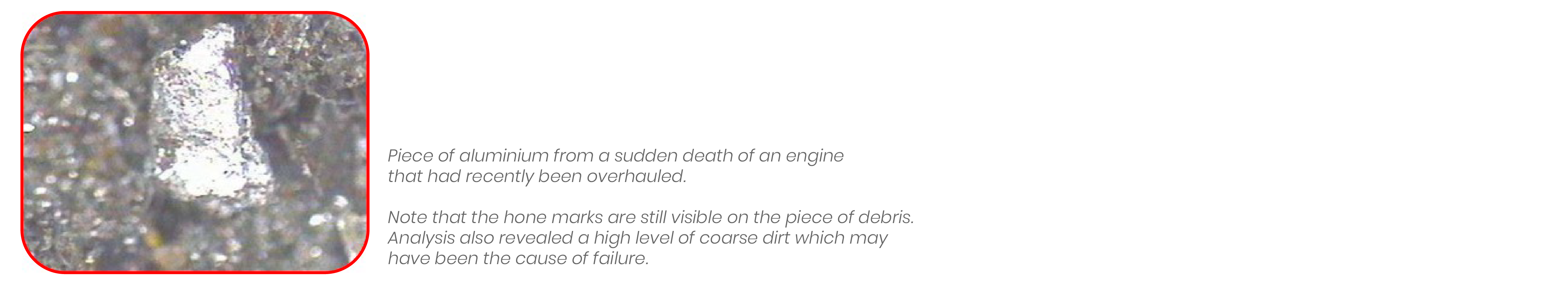

Filter analysis involves the removal of a small amount of the filter medium. This is then agitated with special solvents to remove the debris, the solvent is then filtered through a membrane and examined under a microscope. Basic metal types such as iron, copper, white metal and aluminium are identified and quantified. The same analysis is performed on contaminants such as dirt, rust, carbon grit and oil residues.

The mass of the debris and its PQI is also measured. A photograph is taken of any relevant debris, a subjective description of the debris is made and, where possible, a cause is suggested and corrective action is made. This all contained in printed or electronic format.

For more information on WearCheck’s filter analysis service, contact Steven Lumley at This email address is being protected from spambots. You need JavaScript enabled to view it. or call +27 31 700-5460.

WEARCHECK CONTAINER LAB DESTINED FOR GUINEA

Guinea, West Africa – this is the destination of our latest remodelled container laboratory, where technicians will shortly begin processing used oil samples and other condition monitoring techniques for a Guinean mining company.

The portable laboratory was commissioned by a private mining group, who will run the condition monitoring programme with in-house technicians trained on-site by us. Guinea’s mining industry - mainly iron, gold, diamond and bauxite - accounts for over 50% of the country’s exports.

The unique mobile laboratories are put together at our head office in Westville, South Africa using repurposed shipping containers. The labs have every available safety feature such as ventilation and air extraction systems, fire prevention and more. Each lab is fully-equipped with the latest laboratory instruments and technology, and even has an uninterrupted power supply, air conditioning and burglar bars. As industry needs evolve, the mobile labs undergo constant redesigning.

The laboratory instruments and movable components are carefully packed to avoid disturbance during transport and the container is despatched either by road or by sea, depending on its destination. The container for Atikoo,Guinea will be transported largely by sea from Durban to Conakry.

Our managing director, Neil Robinson, is determined to overcome the lack of infrastructure in certain mining hotspots in Africa through the creation of mobile laboratories in converted shipping containers and placing them on-site. In this way, the local industries benefit from world-class condition monitoring services which otherwise would not be within reach.

Says Neil, ‘Our aim is to make world class condition monitoring services as accessible as possible to operations on the African continent. The extraordinary functionality of the container labs eliminates the need for the customer to supply the services for basic infrastructure such as a building, electricity, internet signal, security and safety features. With these hurdles out of the way, WearCheck then places the designer lab within convenient reach of mining operations.

Once the mobile lab is on-site, a WearCheck technician travels to the location to set up the laboratory and calibrate the instruments. Generally, a local lab manager undergoes training in an existing WearCheck lab and then takes over the reins of the mobile lab along with the necessary technicians. In some cases, the customer manages the laboratory independently.

To ensure that the laboratories always provide our world-class quality condition monitoring services, each mobile laboratory remains connected to the WearCheck South Africa LIMS (Laboratory Information Management System), which allows for quality control of the rest results, and ensures that each sample is diagnosed by our highly-qualified team of diagnosticians. Results are reported via WearCheck’s reporting system.

Offering a wide range of condition monitoring services for the mining sector - including oil analysis, coolant testing, diesel testing and 24-hour sample turnaround time – the mobile labs are also available for use by other industries, such as quarrying, industrial, power generation, transport and shipping operations.

The Guinea-bound container laboratory is the eighth one created by us. The others are operating successfully in Ghana, Mozambique, DRC, Mauritania, Namibia and Burkina Faso. WearCheck operates an additional 14 full-sized laboratories in buildings, in nine countries around Africa and in India and Dubai.

Snake oil: promise vs performance

Have you ever wondered whether fly-by-night lubricating oil manufacturers are held accountable with regards to the alleged additives in their products, and whether their oil actually performs as it claims to on the side of the tin?

In the latest issue of our Technical Bulletin, you can learn about how to avoid “snake oil” (oil with false performance claims), along with tips on being vigilant about knowing the OEM specs for the right lubricating oil for your component and ensuring that this is what you buy. Using cheap (fake) oil can lead to costly damage, so it should definitely be avoided.

Technical Bulletin 71 is only available in the digital version. You can download it for free here.

MEASURING VISCOSITY IS NOW AS EASY AS 1,2,3!

WearCheck has launched a quick, cost-effective viscosity test kit known as the WearCheck Rheo-stick. The Rheo-stick got its name from the word “rheology”, which is a branch of physics that deals with the study of the deformation - and specifically the flow - of matter, such as lubricating oils. The most important rheological property of a lubricant is its viscosity, or a fluid’s resistance to flow. Viscosity is a property of significance as it effects tribological qualities such as friction and wear between interacting metal surfaces. If oil is too thick, the machine is forced to work harder, thereby generating extra heat and using more energy. This results in unnecessary wear and tear on the components. If a lubricant is too thin, the film may not be thick enough to prevent friction. This also creates unnecessary wear and tear.

Now, while the Rheo-stick is an effective on-site viscosity comparator, it does not measure the physical viscosity of the oil in centistokes and cannot give an indication of the chemical composition of the oil nor identify specific contaminants nor degradation by-products.

To order a Rheo-stick kit, please email This email address is being protected from spambots. You need JavaScript enabled to view it. or speak to your local WearCheck representative.

To view the video on how to use this tool, click here.

MONITOR 84

Viscosity, Advanced Field Services and MORE!

The latest issue of our Monitor newsletter is out, and for the first time ever, it is only available as a digital copy. This bumper issue carries stories on Technical Compliance, viscosity index improvers (VIIs), and the details on our brand new Rheo-stick kits for testing viscosity. Our aviation division is also featured, along with an amazing story of how WearCheck SA came to the help of sister company WearCheck UK following an emergency during lockdown. You can also view the 2021 training schedule and other stories.

WEARCHECK SUPPORTS AIR MERCY SERVICE

The SA Red Cross Air Mercy Service (AMS) plays an essential role in the provision of rescue, air ambulance and rural health outreach services to those rendered most vulnerable by geographical, social or economic inequity.

Condition monitoring specialists, WearCheck recently began an ongoing sponsorship of aircraft test kits for the three planes and eight helicopters operated by the AMS.

Technical manager for WearCheck, Steven Lumley, is delighted to help the AMS. ‘We at WearCheck are in awe of how many lives the AMS teams have saved, and how many people are assisted by this wonderful service every single day. To help the AMS reach even more communities, WearCheck has sponsored the condition monitoring of the 11 AMS aircraft.’

‘This gesture is in thanks for the incredible work you all do and the countless lives you save. We want to keep you airborne.’

Mark Lawson, AMO manager, is grateful for the support. ‘The willingness of your lab manager, Meshach, and the team to come in after hours and help us get samples tested and reports issued is really an absolute great show of going the extra mile and supporting us in operating. Excellent client service.’

Pic 1: Condition monitoring specialists, WearCheck, recently began an ongoing sponsorship of the test kits for Air Mercy Service (AMS) fleet. Receiving the first kits are (from left) Marc Lawson, AMS AMO manager, Lunga Sityebi, AMS technical controller and Guy Letellier from WearCheck’s Cape Town technical sales team.