Items filtered by date: Tuesday, 16 December 2025

ESTER-GAZERS SERIES: TYPES OF OIL TESTS AND THEIR SIGNIFICANCE

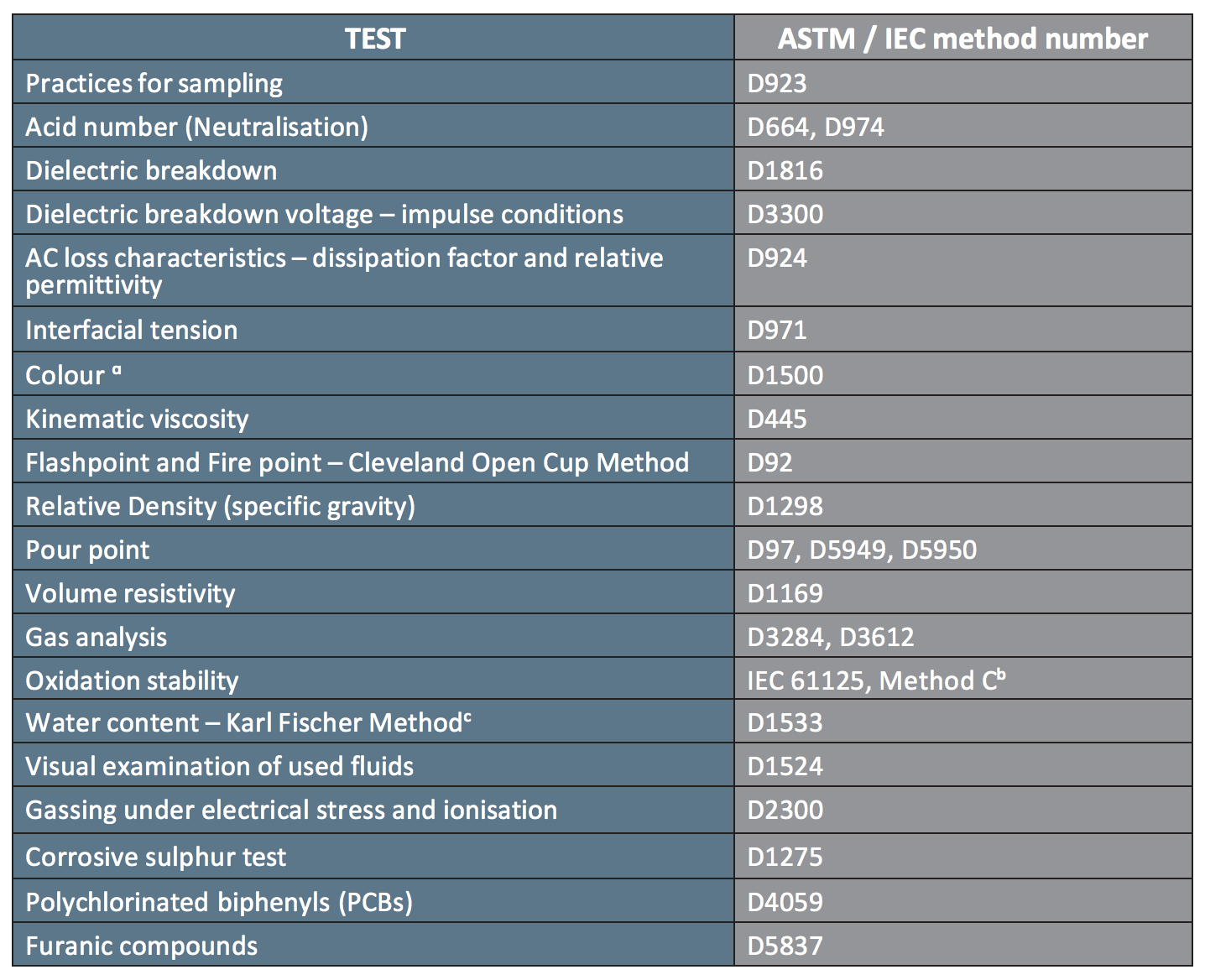

This article is part of a series and is based on reviews of the most commonly applied property tests as per available standards and guides. We will look at how to apply the values of each test to natural ester insulating fluid. The typical values and value limits for new and used ester oils differ primarily from those established for mineral oil.

Due to the inherent differences in chemical, electrical, and physical properties between natural esters and mineral insulating fluids, some standards still need to be updated. For that, some clarification of in-service data is required.

ᵅ NE insulating fluids tinted with dye by the manufacturer should not impact the test beyond the 1.0 limit ᵇ As modified in IEC 62770, Annex A (reducing the test duration from 164h to 48h)

ᶜ Alternative reagents as listed in ASTM D1533 for natural esters as modified in IEC 62770, Annex A (reducing test duration from 164h to 48h).

PRACTICES FOR SAMPLING (ASTM D923)

As with any sample, accuracy is critical to empower the diagnostic services to evaluate the product quality in the sample. Carelessness during the sampling process or contamination of the sample may lead to a misleading result that does not represent the body of fluid being analysed. This can lead to erroneous conclusions and recommendations, which may lead to unmerited expenditure or an incorrect reliability rating of units.

To read more about testing guidelines for natural ester oils in transformers, click here: https://www.wearcheck.co.za/shared/TB85.pdf

ESTER-GAZERS SERIES: TESTING GUIDELINES FOR NATURAL ESTER OILS IN TRANSFORMERS

In this series, we will discuss the different condition monitoring options for the analysis of transformer component performance where natural esters are used as lubricants in transformers.

Lubricants can be categorised in many different ways. One of the most common classifications is by the constituent base oil: mineral, synthetic or vegetable. Mineral oil, which is derived from crude oil, can be produced to provide a range of qualities associated with the oil’s refining process.

Natural esters, derived from 100% renewable vegetable oils, are superior to mineral oil for use in distribution and power-generation transformers of all voltage classes, both new and retrofilled.

Natural esters and mineral oils are miscible and mostly compatible; they are also compatible with halogenated hydrocarbon insulating fluids. Mixing mineral oil and natural esters may or may not significantly impact the typical properties of impact performance. If the property values change, it may or may not be proportional to the ratio of the content of the fluids.

NOTE: If the purpose of using the natural ester oil is to comply with the National Electrical Code, that would require that less-flammable fluids have an ASTM D92 fire point of not less than 300°C and that the installation complies with all restrictions provided for in the product listing of the fluid.

Too much mineral oil contamination of the natural ester might fail to meet the requirements of the Safety Code. The natural ester manufacturer should be contacted to determine the maximum mineral oil content range, that is allowed, to ensure that flammability parameters are met. Typically, a maximum of 7% mineral oil is acceptable.

As a rule, it is not advisable to mix synthetic esters, synthetic hydrocarbons, and high molecular weight hydrocarbons, although they are miscible. Silicone fluid is not miscible with natural ester oils, so cross contamination should be avoided. Typically, natural esters are miscible with non-flammable halogenated hydrocarbons, like PCBs. This might occur when retro filling older transformers that are filled with this insulating fluid. It would be advisable to consult the manufacturers in such a case

To read more about testing guidelines for natural ester oils in transformers, click here: https://www.wearcheck.co.za/shared/TB85.pdf

CHOLERA IN DRINKING WATER

Cholera is the acute diarrhoeal infection caused by the ingestion of food or water that is contaminated with the bacteria called vibrio cholerae.

The infection can cause severe watery diarrhoea. It takes between 12 hours and five days for a person to show symptoms after ingesting contaminated food or water. The bacteria infect adults and children and can kill within hours if not treated.

How is cholera transmitted?

Cholera can be transmitted by ingestion of contaminated food or water. Sudden large outbreaks are usually caused by a contaminated water supply. Outbreaks and sporadic cases are often attributed to raw and undercooked seafood.

What are the symptoms of cholera?

- Profuse watery diarrhoea

- Vomiting

- Thirst

- Leg cramps

- Restlessness and irritability

- Dehydration

- Rapid heart rate

- Muscle cramps

Please note that many people do not develop symptoms, even though the bacteria are in their faeces for several days after infection, and are shed back into the environment – potentially affecting others. Young children can develop severe symptoms due to immature immune systems and under-developed immunity to a wide variety of common germs.

How do you prevent cholera?

- If you suspect that the water is not safe, treat it with chlorine/bleach products, boil it or filter it.

- Wash your hands often with soap and safe water.

- Use the toilet to get rid of faeces safely. It is important to teach young children the importance of using a toilet instead of defecating near a water source in the open.

- If at all possible, avoid travelling to areas or places with active cholera transmissions.

The WearCheck family has grown with the recent acquisition of Set Point Water Laboratories. Incorporating these specialised water analysis skills into our business, means we can offer our clients diverse testing and analysis options. To learn more about our water analysis services, click here: https://www.wearcheck.co.za/testing-analysis-water.

The latest WearCheck’s Monitor newsletter offers valuable insights

Exciting news ! The latest newsletter - Monitor 90 - just hit the streets! ! This issue is jam packed with useful condition monitoring tips and insights. In it, you’ll find in-depth discussions on grease, antioxidants, abrasive wear particles and illuminating paraffin test kits.

Also featured, are stories on our intrepid trainers, who travel to many locations to conduct oil analysis courses and many other condition monitoring courses, including Mobius training.

We introduce you to some of our newest WearCheck staffers and some of our long-serving stalwarts, too. In addition, some of our WearCheck family members have made impressive achievements – Honeywell certification, Machine Lubricant Analyst and KZN colours for angling.

All these stories and many more can be read in Monitor 90, which can be downloaded for free here: https://www.wearcheck.co.za/shared/M90.pdf.

Why maintenance planning & scheduling may fail – part 2

By Shesby Chabaya, HOD, WearCheck Zimbabwe Ops.

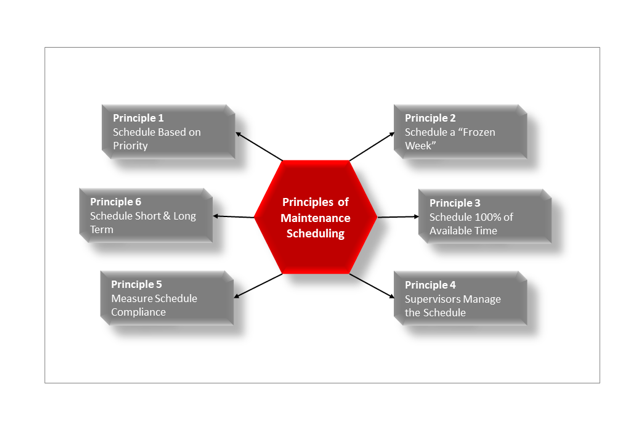

The six principles of maintenance scheduling are key elements to implement when tackling a maintenance “to do” list efficiently. So says Raymond Chizu, sales developer at WearCheck Zimbabwe.

‘The six principles cover prioritisation of tasks based on urgency, incorporating a frozen week, using available time effectively, supervisors actively managing the schedule, and measuring it for compliance, and the principles also allow for long- and short-term scheduling,’ he said.

‘Implementing maintenance planning and scheduling and executing the scheduled tasks with consistency and discipline from all the players, is a sure way to boost productivity in any plant.

‘Additionally, the heightened efficiency boosts team morale. The stable working environment has a positive effect on the amount of work that is completed. When the maintenance team witnesses the scheduled preventative maintenance tasks adding value to a given operation, it smooths the company’s journey along the road to reliability. Inefficiencies such as unplanned equipment failure are reduced, allowing the maintenance teams to work proactively, rather than reactively.

WearCheck’s Technical Bulletin 83 covers the topic in greater detail. You can read the full article here: https://www.wearcheck.co.za/shared/TB83.pdf

Dust contamination and component failure reveals a clear cause-and-effect correlation.

By Shesby Chabaya, HOD, WearCheck Zimbabwe Ops.

The road construction industry is naturally a high-dust environment that requires regular monitoring of all machine components to identify possible threats or risks before they negatively affect equipment.

Recently, the WearCheck team tested an oil sample from a client in the road construction industry. Below, are the details of the findings and lessons learnt with regards to the effects of dust contamination on machine health, as well as how these lessons can be utilised to re-model the oil sampling regime for greater success.

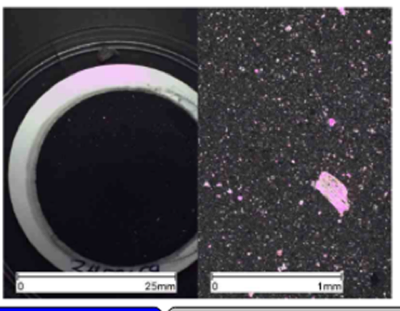

Laboratory findings at the 2,000 hour service were as follows: Iron 639ppm, Chromium 21ppm, Nickel 18ppm, Copper 147ppm, Lead 180ppm, Silicon 156ppm and particle quantifier reaching 12 995MgFe/L. The microscopic particle examination revealed the image below:

|

An interpretation of these findings pointed to evidence of a severe wear situation and a critical silicon (dust) level in the oil. The laboratory assigned critical severity status to the engine, and recommended immediate checking of the air intake system, among other checks. |

An interpretation of these findings pointed to evidence of a severe wear situation and a critical silicon (dust) level in the oil. The laboratory assigned critical severity status to the engine, and recommended immediate checking of the air intake system, among other checks.

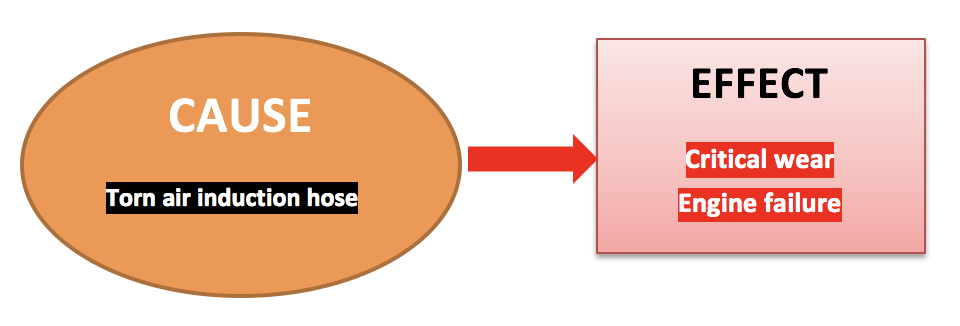

Customer feedback revealed that the engine failed shortly after the service was done. The root cause of dust ingress was discovered to be a torn air induction hose. The tear was not easily visible with the naked eye, as it was located on the inner side of the air induction hose close to the engine block.

Evaluation - the tear on the air induction hose resulted in cement dust bypassing the air filtration system and being sucked directly into the engine, thus accelerating the rate of component wear. This scenario is that of correlation between a cause and effect as illustrated in the diagram below:

The road construction industry involves the application of cement during road construction, and any opening on the engine components will result in severe contamination, which poses a huge risk to component failure.

The torn air induction hose is the root cause of dust ingress, and the effect is severe wear (dust being the catalyst) and consequent engine failure. When an air induction pipe cracks after the air filter, dust enters the air intake manifold and finds its way into the engine. The dust mixes with lubricating oil and is carried through the engine via the lubrication system, acting like a “grinding paste” and wearing out components. The engine may fail to last longer than 300hrs depending on the intensity of dust ingress.

Unfortunately, this engine had not been sampled since the machine was commissioned. Only a single sample came through at 2,000hrs. Had the machine been sampled every 250hrs, the problem could possibly have been picked up earlier and rectified, avoiding a catastrophic failure.

A more regular and systematic oil sampling regime following set oil sampling intervals results in huge cost savings and increased equipment reliability. With a properly set up condition monitoring programme in place, specific parts can be ordered, and maintenance can be planned, thus avoiding interruption to business.

The latest WearCheck’s Monitor newsletter offers valuable insights

Our latest issue of the Monitor newsletter is now live! In this bumper issue, we share knowledge about detergent additives and their essential role in keeping engines clean, and we share advice on dealing with varnish within oil. There is also information about our Lubrigard offering, with a focus on vacuum dehydration.

Added to all this, you’ll find some lovely feedback from our customer survey (thank you to all who participated!), and we are super proud to have South Africa’s very first CAT IV instructor in our Asset Reliability Care (ARC) division. There is also advice on determining drinking water quality, the 2023 oil analysis and Mobius training course dates, our festive season opening hours and lots more.

QUALITY COUNTS AT WEARCHECK

By Prinda Narasi, WearCheck’s quality administrator

November is World Quality Month – an annual celebration embraced by WearCheck with open arms, as it reinforces the team’s fundamental goal – the provision of world-class quality services.

At WearCheck, we take continuous quality improvement (CQI) very seriously. Our services are regularly audited by a range of agencies, including SANS (South African National Standards) and the SABS (South African Bureau of Standards).

WearCheck is currently the only company on the African continent that has earned multiple quality confirmation certificates, which include ISO 9001: 2015 and ISO 14001:2015 certification, and ISO/IEC 17025:2017 accreditation. These are audited regularly, and the company has never failed to have an accreditation or certification renewed.

Peace of mind

We are proud of our relentless dedication to top quality service – it gives our customers peace of mind, knowing that the laboratory results and analytics provided by WearCheck are scientifically accurate.

ISO 14001 recognises international standards implemented by companies to manage their environmental responsibilities, which is very important to WearCheck in line with the company’s earth-friendly work ethics. WearCheck was first awarded ISO 14001 certification in January 2005.

ISO 9001 was first awarded to WearCheck in 1996, and recognises the integrated design, development and provision of condition monitoring services to international standards.

ISO/IEC 17025 is the international standard that sets out the general requirements for the competent, impartial, and consistent operation of laboratories. WearCheck first earned this accreditation in 2012 for its laboratories, Laboratory and Set Point Water Laboratories, a division of WearCheck has also earned this certification.

Benefits for our customers

The ISO 9001:2015 standard is recognised worldwide. Some customers insist on only using certified companies because they know that management systems are constantly assessed and improved.

Further advantages include improved quality and service, delivery on time, right first time approach, minimised incidence of mistakes, improved reporting and communications, better quality products and services, more reliable production scheduling and delivery, and the fact that standards are maintained by annual assessments.

The ISO system promotes an efficient management process and is a mandatory prerequisite to tender for some public sector work. Coupled with the positive message that certification presents to both customers and staff, the system also reduces costs by highlighting time-saving procedures.

THE ROLE OF OIL ANALYSIS IN WIND TURBINE RELIABILITY

Traditionally, South Africa has relied on non-renewable coal resources for the production of electricity. In fact, more than 80% of the country’s power is generated from this fossil fuel. However, as the demand for electricity has surged – and at times, outstripped supply – it’s become critical to consider more viable energy resources. One such resource is wind – an abundant, renewable energy resource that has been used to generate power for thousands of years. Wind is a clean, free and infinite resource that presents viable opportunities for energy production in South Africa.

South Africa’s Integrated Resource Plan (IRP), under the leadership of the Department of Energy (DoE), foresees renewable energy contributing to 42% or 17.8GW of the country’s new generation capacity by 2030. One of the ways they plan to achieve this is with 8.4GW of wind generated power.

While wind energy in South Africa is still, relatively speaking, in its infancy, when compared to more developed nations, the benefits of developing this alternate energy resource have become abundantly clear. Over time, wind energy could help to alleviate the country’s dependence on expensive, harmful and diminishing fossil fuels, while providing a sustainable and secure energy resource for a greater number of people. The message is clear, the transition to clean renewable energy is about making an investment in the future of our civilization and the planet.

According to a new analysis published by the Global Wind Energy Council (GWEC), South Africa added 515 MW of new wind capacity in 2020 cementing its wind leadership on the African continent.

By the end of last year, South Africa had 2 500 MW of cumulative wind capacity installed, representing about 34% of the 7 300 MW of capacity installed across Africa and the Middle East.

However, these two regions represent only a fraction of the total market, with global additions of about 70 GW in 2020 and with the cumulative installed base expected to grow to about 800 GW in 2021.

The DoE’s Renewable Energy Independent Power Producer Procurement Programme (REIPPP) has already overseen the completion of four successful bidding windows with a fifth window launched in March of 2021.

The approved wind farm bids from all four bidding rounds has resulted in the construction of several wind farms over the last few years that collectively house more than 1200 wind turbines with many more installations on the horizon.

The much anticipated fifth round of this procurement program (REIPPP) has been issued with the Ministry of Mineral Resources and Energy (MMRE) which seeks to procure a further 1.6 GW of wind energy.

It is self-evident from the above that in the current environment of renewable energies, wind energy has played an important role as a driver of change in the generation of clean alternative energy. However, this rapid increase has also given rise to several operational and performance issues related mainly to equipment design and maintenance practices.

As the growth in wind energy has continued, the average size and capacity of wind turbine generators has also increased. With this increase in size comes an increase in the cost of operation, and specifically the cost of repairs, downtime, and unscheduled maintenance.

Added to this the estimated life span of wind turbines is about 20 years, compared to conventional steam turbine generator units that have averaged 40 years. The failure rate of wind turbines is about 3 times higher than that of conventional generators. Therefore, reliability is essential to the success of wind energy systems and this requires appropriate condition monitoring.

As a result of external variants, wind turbines undergo constantly changing loads, unlike conventional power plants. Due to these highly mutable operational conditions the mechanical stress placed on wind turbines is unmatched in any other form of power generation and they consequently require a high degree of maintenance to provide cost effective and reliable power output throughout their expected 20-year life cycle.

Ensuring long-term asset reliability and achieving low operation and maintenance costs are therefore key drivers to the economic and technical viability of wind turbines becoming a primary renewable energy source in South Africa.

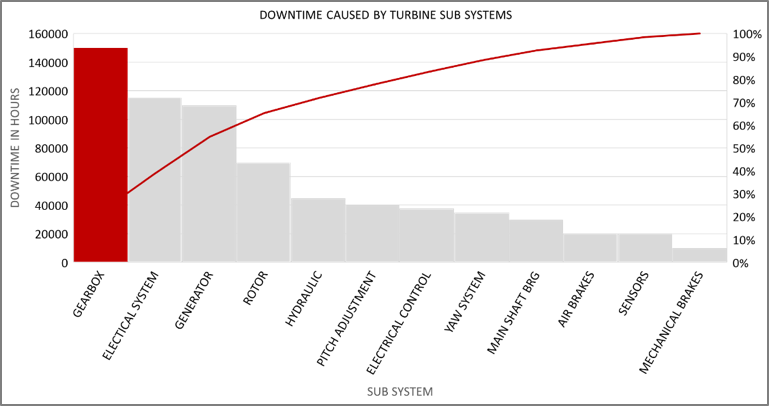

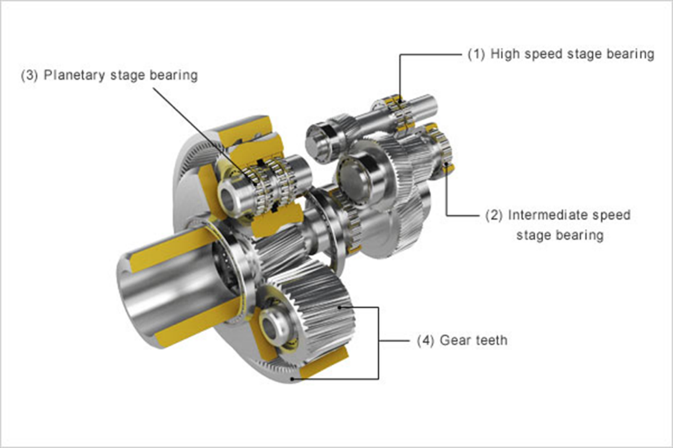

The adequate functioning of most utility-scale conventional wind turbines depends to a large extent on the performance of the gearbox. These gearboxes transform slow speed, high torque wind turbine rotor rotations to the higher speed required by the generator, which converts the mechanical power to electricity. They are typically configured to have planetary gearsets and bearings that require special attention due to their extreme operating conditions and high lifetime expectations.

The wind turbine gearbox is the most critical component in terms of high failure rates and down time. These premature gearbox failures are a leading maintenance cost driver that can substantially lower the profit margin of a wind turbine operation as they typically result in component replacement.

According to a study published by the National Renewable Energy Laboratory (NREL) the mean downtime for gearbox failure was in the range of 6-15 days for a study performed on European on-shore wind turbines over a 13-year time period. The mean downtime could be even longer if a spare gearbox is not available and crane availability is an issue. The same study also looked at data representing about 27,000 turbines ranging from 500kW to 5 MW over a six-year period and found that the cumulative downtime caused by gearbox failures was more than one hundred and fifty thousand hours.

Further analysis found that 76% of gearbox failures were bearing related and mostly due to High Speed Shaft (HSS) & Intermediate Speed (IMS) bearing axial cracks.

Despite significant advancements in gearbox design, they remain an operation and maintenance cost driver due to the very high associated repair costs coupled with a high likelihood of failure through much of the wind turbine’s life cycle.

Therefore, reliability is essential to the success of wind energy systems and this requires appropriate condition monitoring of sub-systems like the gearbox. Its is for this reason that condition monitoring techniques like oil analysis are considered far more effective predictive/proactive tools for achieving optimum gearbox performance as, in the case of oil analysis, the technique can be used to detect the onset of early damage as well as tracking the severity of the damage.

Routine oil analysis is one of the most widely used predictive / proactive maintenance strategies for wind turbines and utilises a test slate that evaluates the condition of the in-service lubricant and helps evaluate the condition of internal mechanical components. In short, Routine oil analysis is used as a frontline defence against premature gearbox failures.

The three main objectives of oil analysis are to monitor the health of the gearbox, monitor the health of the oil and monitor contaminants. Active monitoring of the above provides early warning of abnormal operating conditions that can lead to catastrophic failures if not corrected.

These three objectives can be expanded to six main functions of an oil analysis programme which are to: detect abnormal wear, detect oil degradation, detect contamination, optimise service intervals, avoid loss of production and ultimately, to save money.

The test slate offered by WearCheck as part of their wind turbine oil analysis programme is designed to achieve these six main functions.

To illustrate the potential savings that could be relalised with a proactive maintenance strategy like oil analysis the below cost benefit analysis was performed.

The cost involved in installing a commercial-scale wind turbine can vary significantly depending on the manufacturer of the turbine, the number of turbines, finance and legal costs, construction contracts, the location of the project, infrastructure requirements as well as numerous other factors outside the scope of this document. For the purpose of this analysis the assumption has been made that a utility scale wind turbine costs about ZAR 17 million per MW of capacity.

With replacement of the main gearbox being approximately 10% of the overall wind turbine cost, replacing a 3MW wind turbine gearbox could easily exceed ZAR 5.1 million with transportation, crane rental etc. Over the 20-year expected life span of the wind turbine the main gearbox is expected to be replaced 2.2 times due to failure.

If the gearbox life could be extended by even one year, the replacement costs associated with the wind turbine life cycle will be reduced by ZAR 561,000 per turbine.

Applying this savings to wind farm with 50 – 3 MW turbines equates to a savings of more than ZAR 28 million over the life cycle of the wind farm. The saving does not take into consideration the down time costs associated with loss of electricity production which in itself would be validation for a proactive maintenance programme of this nature.

Oil analysis provides a solid foundation on which to build an effective condition monitoring programme in many applications. In the case of wind turbine gearboxes, oil analysis has the potential to reduce unscheduled maintenance, improve reliability and extend service life. The oil analysis tests performed by WearCheck can help wind farm operators get maximum value from their oil sampling program. When these tests are performed on a routine basis and the results analysed by our experienced technicians, oil analysis can facilitate the maintenance of wind turbine gearboxes and ultimately, support this promising form of power generation on the African continent and beyond. Let WearCheck help you protect the assets that protect our planet.

By Steven Lumley

Dispersant additives, water contamination solutions, mega May milestones and more…

Our latest issue of the Monitor newsletter has hit the streets! In it, you can learn all about the amazing scientific properties of dispersant additives, what happens when a gearbox sump is overfilled, how to minimise hormone contamination in water, our marvellous May achievements, where to enter our 2022 customer survey, and all sorts of other interesting snippets.