Displaying items by tag: Oil technical

The ABC's of oil - part 3

So, we have dealt with the physical and chemical properties of oils and their performance specification but how does the stuff actually work?

Depending on which book, manual or learned journal you read, a lubricant can have as many as two dozen functions. These can be reduced to four very fundamental ones with anything subsequent, more or less, being a subdivision of one of these groups.

An oil must reduce friction, remove contaminants, cool and act as a structural material. An oil cools by absorbing heat and carrying it to the radiator. It keeps the engine clean by carrying contaminants to the filter for removal. It has viscosity and ‘”body” so it can act as a structural material (think of oil as forming a seal between the ring and the bore). But how does oil reduce friction? That is the prime function of a lubricant.

Friction is a ubiquitous part of our daily lives, we spend large amounts of energy just trying to overcome it whether that be walking, driving to work or opening a door. Although friction is often thought of as a negative mechanical characteristic it must be remembered that without it you would not be able to walk nor would the brakes on your car work.

Friction is usually seen as a mechanical problem and the force required to overcome it has long interested engineers. When man invented the wheel it enabled him to move weights around far more easily than dragging them from A to B. What he had done, in fact, was to replace sliding friction with rolling friction, which has a much lower value.

Surfaces that appear smooth and shiny to the naked eye will show peaks and furrows on closer inspection. This does not mean that the component has been poorly machined but components manufactured to high tolerances still have rough surfaces at a microscopic level.

A roller element magnified 200 times.

The rough bits that stick up from the surface are known as asperities. These peaks touch, and very high temperatures and pressures are achieved - this can cause momentary welding of the surfaces to take place. When the surfaces slide over each other, these welds are torn apart.

Whenever friction is overcome, the dislocation of surface material generates heat which can be highly destructive. Additionally, when there is solid friction, wear will take place. Material is lost due to the cutting action of opposing asperities and the shearing of microscopic welds. In extreme cases the combination of high frictional temperatures, welding and shearing can results in complete seizure.

The harmful effects of friction cannot be overemphasised. The job of a lubrication engineer is to control it; lubrication reduces friction by replacing solid friction with fluid friction.

Surfaces in relative motion

When one body slides over another, the force of resistance is known as sliding friction. If a ball were to roll over a metal surface, the relative velocity of the points of contact are actually zero and this results in rolling friction. However, there will always be some deformation of the contacting surfaces, so some sliding friction is always involved. Tests have shown that rolling friction is not influenced by the presence or absence of a lubricant, however, the deformation and the presence of sliding means that the oil is a very necessary component of a ball bearing.

The friction that exists between two bodies in relative motion can involve an appreciable energy loss that needs to be minimised. This is achieved by feeding a lubricant between those surfaces in order to replace solid friction with fluid friction.

Unfortunately, friction can never be eliminated as there will be internal viscous drag (fluid friction) of the oil.

In ideal situations the oil will cause the surfaces to separate completely; where this is not possible the oil can still keep friction to manageable proportions.

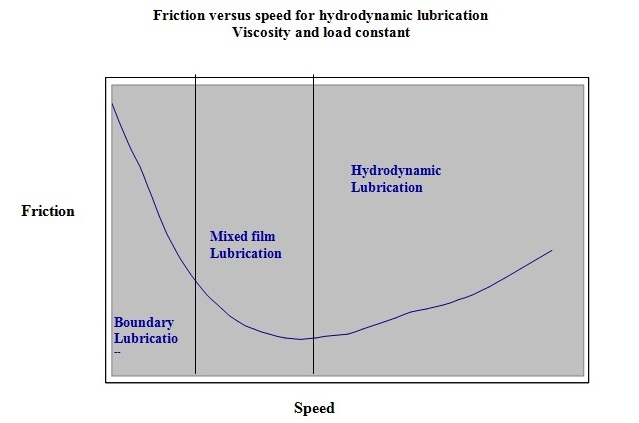

Three parameters need to be considered when looking at the various lubrication regimes: the speed at which the surfaces are moving relative to each other, the load placed on those surfaces; and the viscosity of the oil. Ideally, there should be high speed, low load and high viscosity; under these conditions the surfaces would always be separated. Unfortunately we do not live in an ideal world.

In the case of a plain bearing and journal there will always be a small amount of oil between the mating surfaces. However, at start up, the speed will be zero and the lubricant will not keep the surface completely apart – some of the asperities will touch. This is known as boundary lubrication; in this situation it is the additives in the oil that help to minimise friction.

As the speed of the journal increases pressure differentials cause oil to be sucked between the bearing and the journal, this is known as mixed film lubrication. At this point the surfaces are not quite separated but are supported by a full fluid film.

The speed becomes fast enough for the surfaces to become completely separated and the solid fiction is replaced entirely by fluid friction; this is known as hydrodynamic lubrication.

Unlike solid friction, fluid friction is dependent on speed and will gradually increase. Friction is actually at a minimum during the mixed film regime. The graph below illustrates this.

Finally, there is another regime that goes under the rather grand name of elastohydrodynamic lubrication. We have considered mating surfaces that have the same geometry, in a similar way that spoons stack together. But what about a roller bearing where the mating surfaces are not of the same shape?

Pure rolling friction should not require lubrication but the contacting surfaces deform elastically when placed under pressure or load. Oil is drawn into this contact but, because this takes place over a vanishingly small area, huge pressures are generated of the order of one and a half million kPa. At these pressures, the lubricant takes on the consistency of window putty (reversibly) and is capable of keeping the sliding friction to manageable proportions in this type of situation.

It is not easy to cram so much information into such a small space but it is hoped that this gives some background on which oils are available and how they work. Remember the five “rights” of oil: use the right product, in the right place, at the right time, in the right quantity and with the right attitude.

John Evans

Diagnostics Manager

The ABC's of oil - part 2

In part 1 we dealt with the physical properties of oil, we will now discuss the chemicals that are added to the base stock in order for the oil to do its specific job? In other words, if I buy a can of oil, how good is it?

The most important thing to realise at this point is that if you buy oil from any reputable oil company there is no such thing as a ‘bad oil’. You can certainly get cheap oil and you can pay up to R200 a litre if you really want to; you get what you pay for but there are no ‘bad oils’.

So, how do you know how much bang you are getting for your buck? Engine oils (and to a lesser extent, gear oils) are graded according to performance specifications. There are any number of international bodies that are equipped and certified to carry out testing to confirm whether a certain product meets internationally accepted performance criteria. The one that most people are familiar with is the API or American Petroleum Institute although Europe has the European Automobile Manufacturers’ Association, and in Japan it is JAMO; even our own South African Bureau of Standards (SABS) has specifications for lubricants. In this article, we will only look at the API which grew out of the United States military classification system.

Systems such as the API came into being when engine manufacturers started communicating their needs to the oil companies.

When an engine oil is blended, many chemicals (additives) are added to the oil. These additives impart certain properties to the oils enabling them to function in a desired manner. Below is a list of some typical additives and their functions:

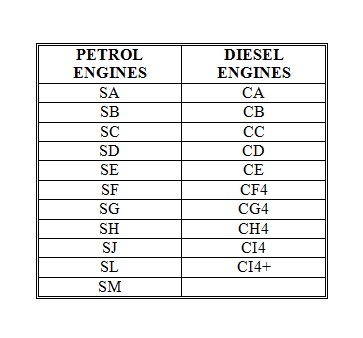

The right combination of the right additives in the right amount are blended with a refined crude oil (base stock) in order for an oil to do its job. The API grades these oils on how well they can do that job. Most API specifications are of the format Sx/Cy where x and y are letters of the alphabet; the first half of the designation refers to petrol engines and the second half to diesel engines. The full range is shown below:

The “S” designates petrol engines and stands for spark as these are spark ignition engines; the “C” stands for compression as diesel engines employ compression ignition. Basically, the further you go into the alphabet, the ‘better’ the oil is. What this actually means is that an SM oil has passed a greater variety and more stringent performance tests than an SG oil.

Most engine oils will generally meet both an S and a C classification, for example SL/CF4. The diesel specification is usually lower as the combustion of diesel puts much higher demands on the lubricant; the combustion by-products of diesel are much more aggressive than for petrol.

In order to grade engine lubricants, engine manufacturers have designed a series of tests to be carried out under scientifically controlled conditions. Most major engine manufacturers are involved and, in order for an oil to achieve an API specification, all tests must be passed to the level stipulated by the manufacturers.

These performance tests do not look at overall performance, but specific characteristics of the oil under test. For example, the Caterpillar IG2 test is used to determine the ability of the oil to protect against ring sticking, wear and accumulation of deposits under high speed turbo-charged conditions. The Peugeot TU3 test is used to measure the ability of the oil to protect against valve train scuffing.

All tests are defined by the American Society for Testing and Materials (ASTM International) which works closely with the API and the SAE. The SAE defines the need for a new specification (in conjunction with oil companies and additive manufacturers), the ASTM develops the tests and the API defines the new oil category. This is a very lengthy, complicated and consultative process, as all stakeholders need to be involved.

This explains why a simple oil analysis laboratory cannot determine if an oil meets a particular specification or not. Chemical and physical tests cannot replace actual performance testing; the costs to an oil company trying to get a new product certified runs into millions of dollars.

Whether a product meets a specification or not is actually an act of faith as it is not within the means (in terms of cost or facilities) of the man in the street to have it checked.

Oil base stock and a selection of additives.

The gear oils are graded in a similar way by the API. These oils will have what is known as a GL rating, with “GL” standing for “gear lubricant”. The GL rating measures the level and effectiveness of the EP (Extreme Pressure) additive in the oil. EP additives prevent scoring and scuffing of gears under high load applications.

The scale runs from GL1 to GL6 (although GL6 has been technically obsolete for many years), GL1 having the lowest EP level and GL6 the highest. Oils typically found in automotive applications are GL4 and GL5. GL4 oils would normally be used in a manual gearbox application and GL5s in the differential.

The GL4 designation became obsolete in 2010.

As environmental legislation puts heavier and heavier demands on engine manufacturers, the engine manufacturers are putting heavier and heavier demands on the lubricants. Rather than put the muck in the atmosphere, let’s put it in the oil; engine oils work very much harder than they did 10 years ago.

One group of oils that hasn’t been discussed yet needs to be touched on briefly - synthetic lubricants.

Crude oil is removed from the ground, refined and then additives are blended to produce the finished product. The refining process removes undesirable entities from the crude oil until a finished product is arrived at which will do the job. This does not remove all the nasties, merely the ones we really cannot live with.

A synthetic oil is a base stock that has been designed, in a laboratory, with all the desired properties and none of the undesirables. This makes synthetic lubricants vastly superior to mineral ones, however, there is a cost involved. Synthetic oils are very good but they are very expensive.

So, we have dealt with the physical and chemical properties of oils and their performance specification but how does the stuff actually work?.

More to follow in part 3.

The ABC's of oil

The ABC's of oil by John Evans, Diagnostics Manager, WearCheck.

When purchasing a can, drum or tankerful of oil, how can you be sure of what you are buying, where you can use it, and what quality you are getting for your money? On every can of lubricating oil there is (or should be) a series of numbers and letters that describe what is inside. This article will look at what those numbers and letters tell you.

Oils have both physical and chemical properties. They consist of a ‘base stock’ which is refined crude oil blended with various ‘chemicals’ that impart desired properties to the lubricant enabling it to perform its job.

Let’s look at the physical properties first:

The most important physical property of an oil is its viscosity. Viscosity is defined as a fluid’s resistance to flow, under gravity, at a specified temperature. What that simply means is - ‘how thick is the oil?’ Thick oils do not flow so easily and have high viscosities, thin oils are quite fluid and have low viscosities. Think how differently compressor fluids behave when poured, compared to gearbox oils.

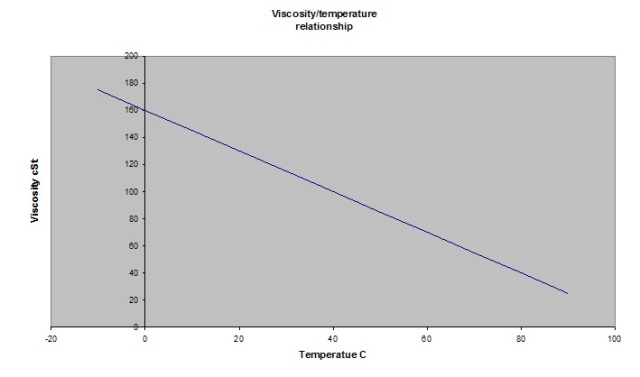

The actual property of interest is called kinematic viscosity, its units are known as centistokes and one centistoke is one millimetre squared per second. It is important to remember that as temperature increases, the viscosity of an oil decreases.

The SAE or Society of Automotive Engineers has a grading system that describes the viscosities of oils that are used in all automotive applications from motor scooters, family cars and4X4s to buses, trucks and bulldozers.

There are two parallel systems, one for engine oils and one for gear oils. The number and letters associated with the SAE system are shown below.

The reason for two systems is that gear oils have very different chemical properties to engine oils as they have to perform different functions. You might get away with putting an engine oil in a gearbox but you certainly won’t do your engine any good by putting in a gear oil. If it is a big number (more than 60) it is a gear oil, if it is a small number (less than 70) it is an engine oil. This is to avoid confusion. It is important, however, to note that both series cover the same range of viscosities. An SAE 30 engine oil is just as thick as an SAE 85W gear oil.

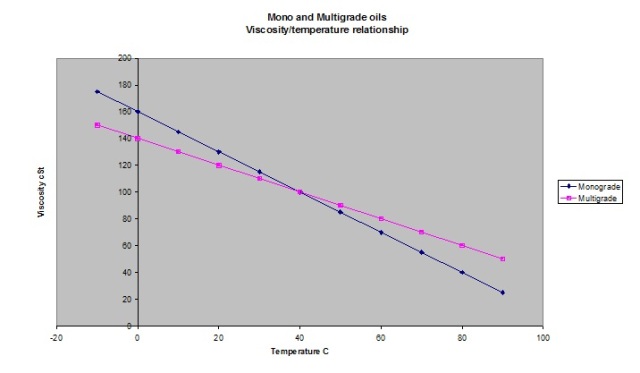

You will note that some of the grades have a ‘W’ after them, these are the lower or thinner grades that function better at low temperatures as all oils will be thicker when they are cold. These grades can also be blended with other non-W grades to form what are known as multigrade oils. Monograde oils have such designations as SAE 10W or SAE 90 whereas the multigrades have names such as 20W50 or 80W90. Remember, if you increase the temperature of an oil you will decrease its viscosity; a temperature viscosity graph may look like this:

On a very cold winter’s morning, the temperature might be as low as -10 degrees Celsius; but at operating temperatures, the engine will have heated the oil to 90 degrees Celsius. Ideally,you require a fairly thin oil that will flow at low temperatures but doesn’t thin out too much as the engine reaches operating temperature. Multigrade oils are formulated to perform under exactly these conditions as they thin out less than monograde oils when they are heated. The following graph is an exaggerated illustration of how the two types of oils behave:

The advantage of using a multigrade oil is that its viscosity is more stable over a greater range of temperatures. In effect, a 20W50 will behave like an SAE 20W when it is cold and an SAE 50 when it is hot providing protection for your engine over a wide range of conditions. The ‘W’, in fact, stands for “winter".

Well, that has dealt with the physical properties of the oil, but what about the chemicals that are added to the base stock in order for the oil to do its specific job? In other words, if I buy a can of oil, how good is it?

More to follow in part 2 of The ABC’s of oil.